Topics in Photographic Preservation 1988, Volume 2, Article 3 (pp. 12-24)

This paper is a progress report of research into the abrading propensity of some materials used in the interleaving of historic photographic albums and prints. The aims of the project are to:

A test procedure has been developed and is described in this paper. Three interleaving materials have been tested with satisfactory results. While this project is confined to the testing of album interleaving materials, it is hoped that the findings will be useful in the evaluation of materials used as enclosures for unbound photographs. Many of the same materials are used for both purposes.

There are many features typical to the structure of historic albums which contribute to the deterioration of the photographs housed within them. Some of these are:

When deterioration in the form of staining caused by prolonged page to page, photograph to photograph contact is present, that deterioration can be arrested with the addition of an interleaving sheet. An interleaf should also protect the photographs in an album from further physical damage by mitigating the effects of abrasion and uneven pressure.

The chemical interactions between some historic photographic processes and enclosure materials have been addressed in recent and continuing studies. However, the physical interactions between these two components have been little explored.

The test procedure developed to measure the abrading propensity of interleaving materials consists of two parts: the abrasion mechanism or means by which abrasion is produced in a laboratory setting, and the rating of the degree of abrasion to yield a numerical value. The second aspect has turned out to be the more challenging one. The term abrasion is used here to denote all forms of surface marring.

The rub testing was carried out at the Image Permanence Institute in Rochester using a manually operated rub tester called the UGRA abrasion tester, which is manufactured by Huber. This machine enables one to move two contacting surfaces, in this case, the photograph and interleaving paper sample, against each other, producing abrasion. The machine consists of three parts: 1) the guiding frame with cycle counter, 2) the abrasion carriage which glides along the frame and 3) a metal block with an area of 50 × 52 mm2 and mass of 500 g, producing a total load of .27 lb/in2.

The photographic print is placed face up on a smooth, flat surface under the guiding frame. The interleaving paper sample is placed on the abrasion carriage with the side to be tested facing the photograph's emulsion. The weight is placed in the abrasion carriage, over the paper sample. The abrasion carriage is moved backward and forward manually. The abrasion movement is linear–in a path 2 × 10 cm. The number of cycles is recorded by the counter device. One cycle equals one backward and forward movement. The machine is designed so that hand pressure applied to the carriage does not contribute to the load. Several variable test conditions were tested for their effects on the degree of abrasion produced. The rub testing was performed using two different loads, .27 lb/in2 and twice that, .54 lb/in2. The heavier load was achieved by placing steel weights on the machine's 500 g metallic block. The number of cycles per rub test was also varied; sets of 10, 20, 40, and 80 cycles were run per paper sample.

The testing was carried out in a climate-controlled room at the Image Permanence Institute. The RH was 50% and the temperature 70°F. Relative humidity can have a significant effect on the abrasion resistance of photographs, as the moisture content of photographic supports and emulsions changes with changing relative humidity. The effects of humidity on abrasion are discussed at length by Carroll and Paul in their article “Test Methods for Rating the Abrasion Resistance of Photographic Film” in Photographic Science and Engineering, volume 5, number 5, 1961. All paper samples and photographic prints were preconditioned in the testing environment for 20 hours prior to testing.

Three papers were selected as samples for this round of abrasion tests. They are:

A = a buffered bond paper, 20 lb.

B = a 100% cotton photographic storage paper with a density of 120 g/m2 and

C = an acid-free unbuffered tissue, .001 in.

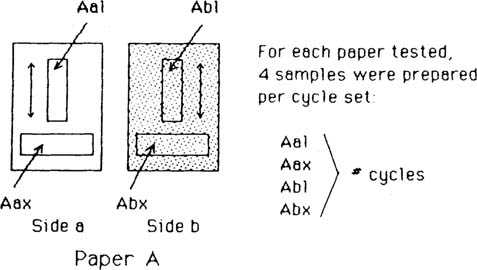

These three were chosen because they are used frequently as interleaves and were expected to yield a broad range of rub results. Four discrete samples were cut from each paper type. This was done to enable the testing of the effects of the variables of grain direction and side. This brings the total number of variables for each paper tested to 32: 2 grain directions × 2 sides × 4 cycle sets × 2 loads.

The photographic paper used to prepare the prints is Kodak Polycontrast Rapid II RC with paper surface F (glossy). The paper was exposed to a tungsten light source for a predetermined period to produce a black image and processed following the instructions provided with the paper. Each 8 × 10 print was cut into three sections, each 3 × 8″ as required by the rub tester.

It would be misleading to suggest that the rub testing phase of the project proceeded altogether smoothly. The procedure was settled on after much trial and error. The use of another rub tester, the Sutherland rub tester was rejected early on because of the uneven results that it gave. The unevenness of the abrasion produced using this machine seemed to be caused by uneven wear on the two rubber pads at either end of the weights. In contrast, the abrasion path produced using the UGRA is quite even. The UGRA is preferable for a number of other reasons too: the load exerted by the metal block is less than that of the Sutherland Rub Tester, making the test conditions a better recreation of real-life conditions within a photographic album; also, the load can be increased to a particular preference by simply adding weights to the block.

The degree of abrasion produced on the photographic prints was measured using colorimetry. Color measurements were made at the Munsell Color Lab, Rochester Institute of Technology (RIT) using a Milton Roy circumferential spectrophotometer with 45°/0 geometry. This means that the sample (in this case, photographic print) is illuminated by a light source placed at an angle of 45° to its surface, and viewed along the normal or at a 90° angle. Before the measurements were begun, the scale of the instrument was expanded by a factor of 20 in order that it would “see” the subtle differences between the degree of abrasion of the samples. This expansion was achieved using a dark grey reference tile. The machine was specially calibrated for this series of tests.

The measurement procedure was simple. Each photograph was brushed off and secured at the port. The instrument averaged values of two readings taken across the abrasion path. A number of values are recorded on the print-out, including the tristimulus values which represent hue, chroma, and brightness. The useful value for the purpose of this project is DE, which represents the difference in perceived color, based on the three tristimulus values, between the abraded photographic print and the control print, which has received no abrasion. The DE value represents a change in brightness since there theoretically is no change in hue or chroma with black prints. The higher the DE value, the greater the degree of abrasion.

Why was the colorimeter chosen as the instrument to measure the degree of abrasion?

A number of other instruments were tried out before the colorimeter was used. In fact, at the outset of the project the plan was to use a glossmeter to measure the degree of abrasion of the photographic prints. Two types of glossmeters were used, a Hunter glossmeter with 20° geometry, that is, with the illuminant at an angle 20° from the normal, and a Dorigon abridged goniophotometer. Neither instrument was able to distinguish between the unabraded and least abraded samples. This was seen as a disadvantage since the least abraded samples most closely reproduce the amount of abrasion occuring in real life. The measurements made with the Dorigon suggested that a large difference between the incident light angle and receptor angle would be desirable–as is the situation in the colorimeter with 45°/0 geometry. Glossmeters are designed to measure specular gloss, which can be defined as the degree to which a surface simulates a mirror in its capacity to reflect light. The colorimeter measures reflection haze which is the condition produced by the abrasion on the photographic prints.

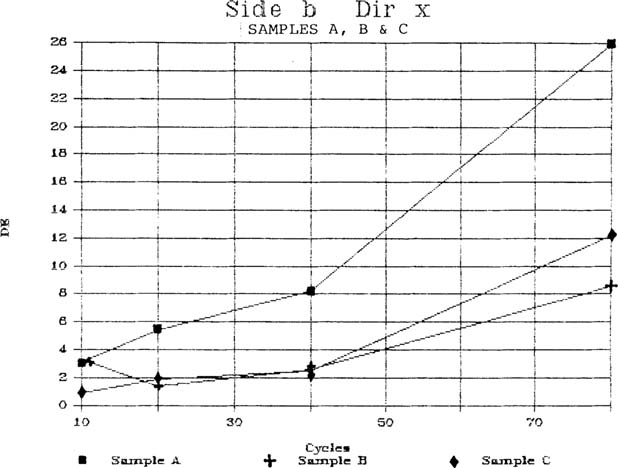

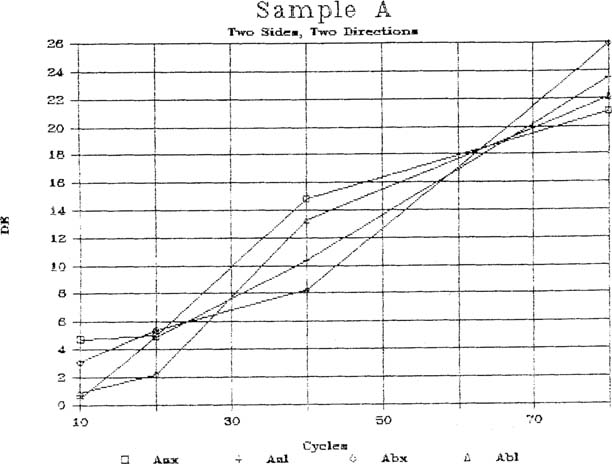

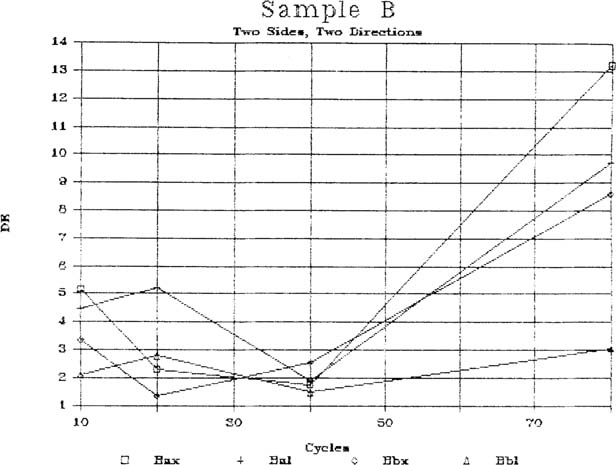

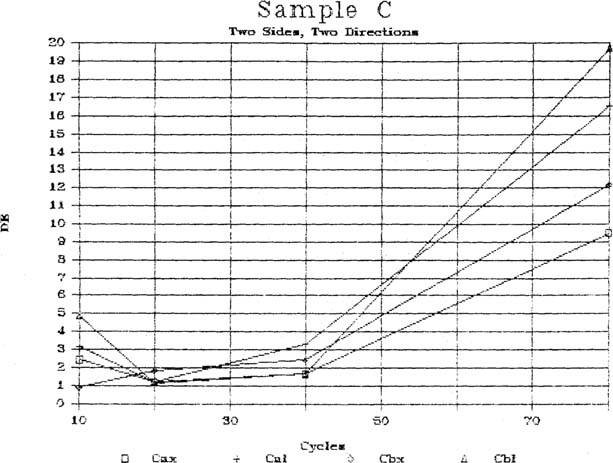

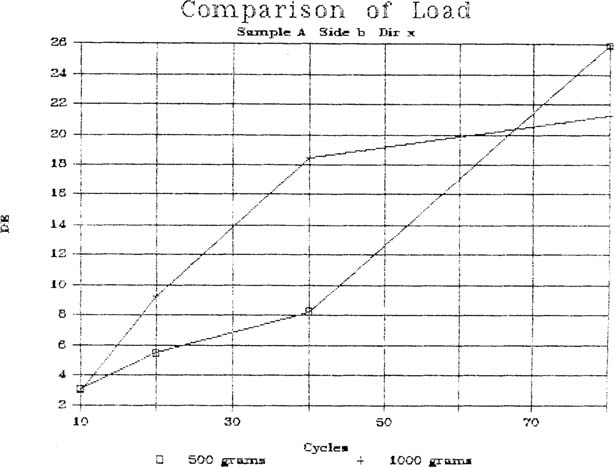

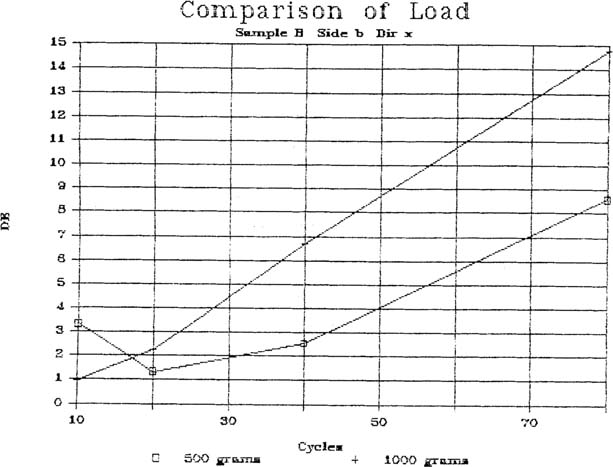

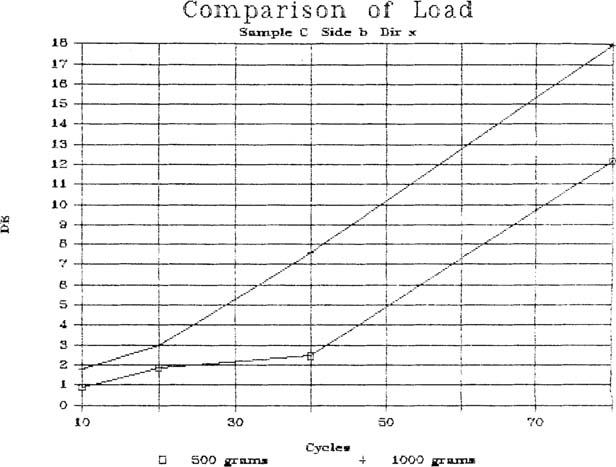

The following series of graphs illustrates the results of the rub testing. In all of the graphs, DE values are plotted against the number of cycles. Note that the upper case letter (A, B or C) represents paper type, with A = buffered bond, B = photographic storage paper and C = acid-free tissue. The lower case letter (a or b) stands for side. The x means cross grain direction and I, long. In all of the graphs the applied load is .27 lb in2 except for those three entitled “Comparison of Load” in which the two loads are compared: .27 lb/in2 and .54 lb/in2 The DE of the control is .17. The higher the DE value, the greater the reflection haze, the greater the degree of abrasion.

Some observations can be made based on the DE values:

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Whether the DE measurements are repeatable and reproducible using another machine is a question that will be addressed as the testing continues. Also, increasing the variables to assure a broad range of results and the validity of the procedure will be considered. Two ways to do this would be to test an additional photographic process, preferably an historic one like albumen or collodion, and to conduct the abrasion tests in a different environment, say 20% RH.

Figure 1

The author would like to thank the following people without whom she would not have been able to complete this part of the project: Chester Daniels at RIT, for loaning the rub testers; Roy Berns, Head of the Munsell Color Lab at RIT and Jack Carroll of the Physical Performance Unit at Kodak, for their help in finding the most appropriate method of rating the rub results; and James Reilly, Peter Adelstein and the staff at the Image Permanence Institute, for their advice and encouragement in planning and carrying out the testing. This project was made possible by a grant from the Samuel H. Kress Foundation.

F.W. Billmeyer and M. Saltzman. Principles of Color Technology. Second edition. New York: John Wiley & Sons, 1981.

J.F. Carroll and J.O. Paul. “Test Methods for Rating Abrasion Resistance of Photographic Film.” Photographic Science and Engineering, Vol. 5, No. 5 (September-October 1961): 288–296.