Topics in Photographic Preservation 1988, Volume 2, Article 9 (pp. 69-91)

The use of Fuji Ag-Guard treatment for enhancing the stability of black & white photographic images has been examined. The effectiveness of the Ag-Guard process compared with selenium toning and with no after-treatment was evaluated by means of an accelerated aging test involving hydrogen peroxide fuming. The Ag-Guard treatment appears to be very product dependent. Used at full strength it compared favorably with selenium in the treatment of some products, but was less effective than selenium toning in the treatment of other products.

The processing procedures commonly recommended and used for b&w photographic films and papers have long been considered adequate for producing silver images with the necessary stability for long-term display and storage. However, silver images can discolor, and even fade, when exposed to oxidizing gasses. High temperature combined with high humidity tends to hasten such image deterioration. Unfortunately, many urban and industrial areas contain sufficiently high concentrations of harmful gases to bring about gradual or even rapid deterioration of silver images. B&W prints made on RC base papers are especially susceptible to oxidation and discoloration, but all other fine grain silver images are also vulnerable.

The resistance of silver images to degradation by atmospheric pollutants or other harmful chemical substances can be markedly enhanced by transformation of the metallic silver into a less reactive silver compound, or by a protective coating. Usually, the preferred method is toning, such as selenium toning which yields silver selenide; or sulfur toning which yields silver sulfide. Of these two, selenium toning is often favored, because usually it effects less of a change in image color and contrast than does sulfur toning. However, some changes in image quality are generally encountered. Moreover, selenium and sulfur toning require extra processing steps, including prolonged washing, before and after the lengthy toning treatment. And, selenium in some forms is a known carcinogen. As a result selenium toning is viewed as a potential hazard by many laboratory technicians.

A new and simpler process for enhancing the stability of silver images, called Fuji Ag-Guard, was introduced in Japan in 1984, by the Fuji Photo Film Co., Ltd. The advantages claimed for Ag-Guard are:

Excellent image stability

No changes in image color and image contrast

Simple treatment procedure through a one minute immersion in the Ag-Guard solution

Easy preparation through use of a liquid concentrate

Good stability of the concentrate

The principal ingredient of this new “toner” is a very stable organic sulfur compound. This compound has an active group which readily reacts with silver ions, such as those generated by the action of oxidizing gases on b&w silver images. The reaction yields a very stable organic silver salt which is resistant to further oxidation. What happens, in effect, is that a protective layer is formed at the surface of the silver grain which stops formation of additional silver ions through oxidation.

Samples of the product were obtained from Mr. Peter Krause, through the kind efforts of Dr. Haruhiko Iwano of Fuji Photo Film Co., Ltd. Dr. Iwano also arranged for the accelerated aging tests that were carried out with treated and untreated samples of b&w films and prints.

Ag-Guard – In previous experiments it was determined that use of the Ag-Guard at the recommended dilution was not as effective as selenium. Therefore, for these tests, the Ag-Guard solution was used full-strength.

Selenium – The selenium toner was prepared by combining: 8 oz. of Kodak Selenium Toner Concentrate, and 6 oz. of Heico Perma Wash concentrate, with Water to make 1 gallon of working solution.

To avoid possible contamination all measuring beakers were glass.

The following photographic papers and films were used for the test:

Kodak SO-015 (Direct Duplicating) Film. Exposure was made using a Kodak calibrated 21-step wedge. This film was processed in a Hope 134 B&W Processor which has been altered to provide increased wash water flow. Film processed through this machine meets archival standards for residual hypo content without further treatment. The most recent Plus X Film tested by the methylene blue method for residual hypo yielded values of 0.068 g/m2.

Kodak Kodabrome RC F-2 Paper. After exposure using a Kodak calibrated 21-step wedge, processing was made in a Kreonite BW-31-62 processor using Kodak Dektomatic Developer and Rapid Fixer. This is an unmodified machine which does not produce prints of archival quality.

Kodak Kodabromide Fiber-Based Paper. After exposure using a Kodak calibrated 21-step wedge, these prints were tray processed in stainless steel trays using Kodak Dektol Developer and Rapid Fixer. A two-bath fixing method was used, followed by holding in a Kreonite circular washer with spray arm for approximately one hour. This was followed by a 20 minute wash in a Kostiner Archival Washer. Drying was on a Pako water-jacket rotary dryer.

Ag-Guard treatment was for one minute. Washing after this treatment is not recommended, and was not given.

Selenium toning was accomplished by continuous agitation for four minutes, followed by a 20 minute wash.

Fiber-based prints were dried using a Pako Dryer as noted.

The film and RC prints were hung and air dried.

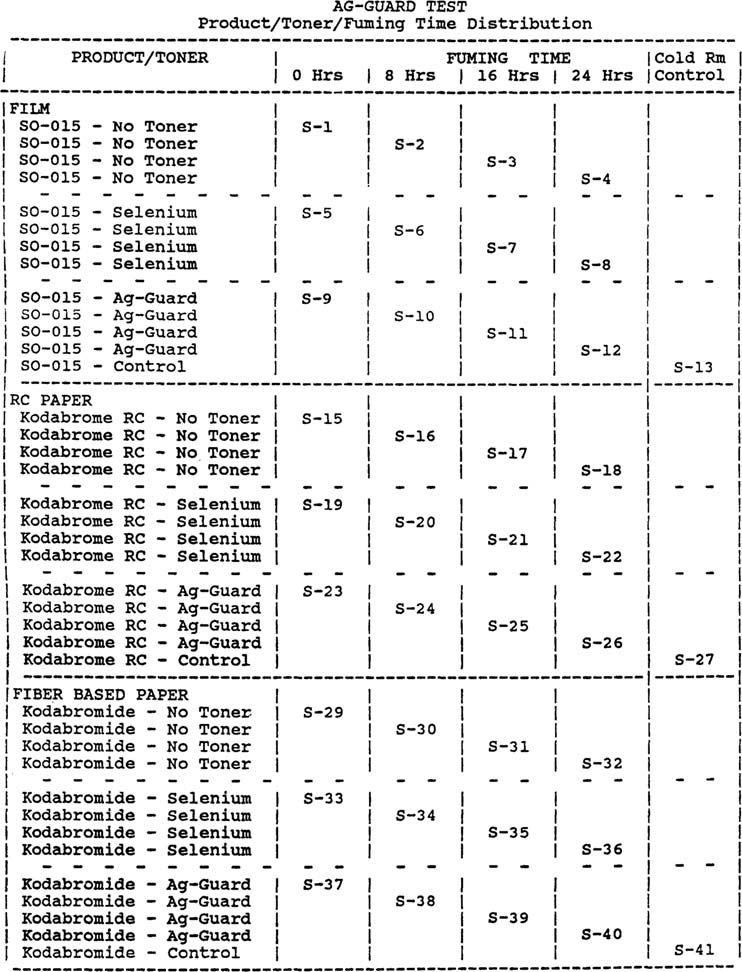

Samples of each of the three materials tested were prepared according to the accompanying matrix (Fig. 1). All were sent to Dr. Iwano at Fuji's Ashigara Research Laboratories for accelerated aging. All samples, except those labeled as “cold room samples”, were included in the shipment. In this way all the samples, including those which were not fumed, encountered the same conditions during shipment.

Fig 1: Product/Toner/Fuming Time Distribution.

The samples labeled “cold room samples” were kept in the Smithsonian's photographic cold storage room at 5 degrees C., and 28% RH. These were later used as control samples to check the accuracy and repeatability of densitometer readings.

Samples which were sent to Fuji for accelerated aging were treated with hydrogen peroxide fumes in a special test chamber to determine the effectiveness of the various treatments. According the the matrix shown in Fig. 1, fuming times were set at 8, 16, and 24 hours.

According to the report returned by Fuji, “No preliminary conditioning was made… The samples were fixed on hangers by punched holes and inserted in the testing chamber conditioned at 40 degrees C, and 70% RH. The chamber [had] two glass containers filled with 6% hydrogen peroxide solution at the bottom.

“Five fluorescent tubes [were] provided in the testing unit so that samples [were] exposed to the florescent light through a translucent plastic separating plate. The distance from the light source to the sample plane [was] 60 cm. Both [the] light source and sample plane…faced each other and [were] fixed (not revolved).

“The first two hours of peroxide treatment [was] the dark period, then the next two hours [was] the lighted period. The lights [were] turned on and off every two hours.

“If peroxide treatment is done totally [in the] dark”, Dr. Iwano notes, “silver mirror is more prone to be generated. On the other hand if it is done [in a] continuous lighting condition, more yellowing occurs. We thought,” he adds, “that the cycling may be a better simulation of aging process occurring day and night.”(1)

Readings both before and after accelerated aging were made on a MacBeth RD519 reflected densitometer using status D filters, or a MacBeth TD504 transmitted densitometer using status A filters.

Changes in both Visual and Blue densities were read. Visual readings were also taken after toning and before fuming to determine density changes caused by the toning process itself.

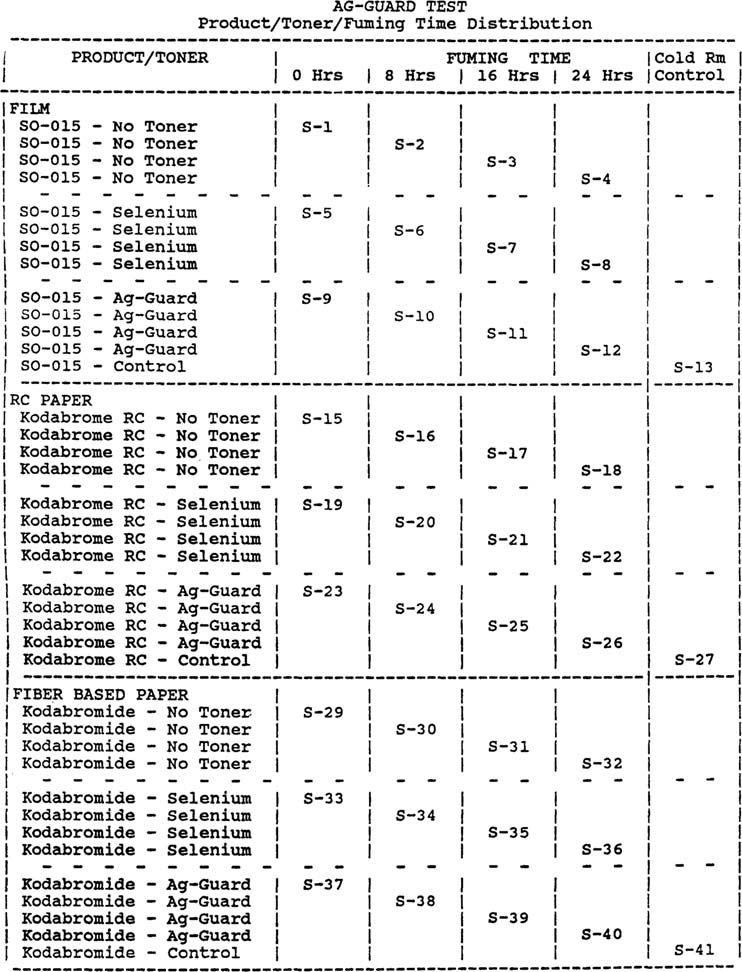

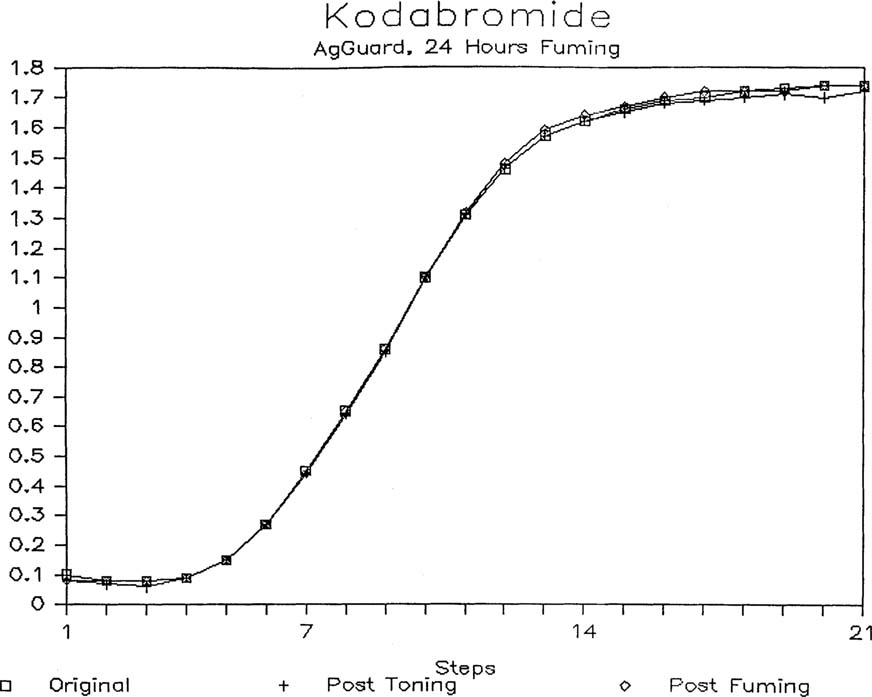

In addition to the numeric readings and resulting graphs obtained from the densitometer, a visual appraisal was made following accelerated aging, and tabulated based on the Drago & Lee ranking scheme(2), (Fig. 2).

Fig 2: Scale to determine Extent of Attack of Silver Images by Hydrogen Peroxide Fuming Test, by Drago & Lee.

(Drago, F.J. and Lee, W.E. “Review of the Effects of Processing on the Image Stability of Black-and-white Silver Materials” Presented at the Second International Symposium: The Stability and Preservation of Photographic Images, Society of Photographic Scientists and Engineers, The Public Archives of Canada, Ottawa, August 25-28, 1985.)

It was determined that the effectiveness of the Ag-Guard process varied greatly with the product on which it was used.

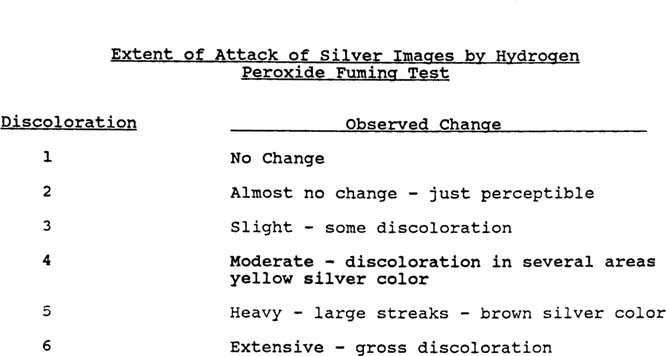

Kodabromide Fiber-Based Paper – Best results from the Ag-Guard were obtained from the Kodabromide fiber-based paper. Both the resulting graphs and visual appraisal showed no statistically significant change between the original readings and those made after 24 hours fuming. (Fig 3 and 4)

Fig 3: Graph, visual density effect of Ag-Guard on Kodabromide Paper after 24 hours fuming.

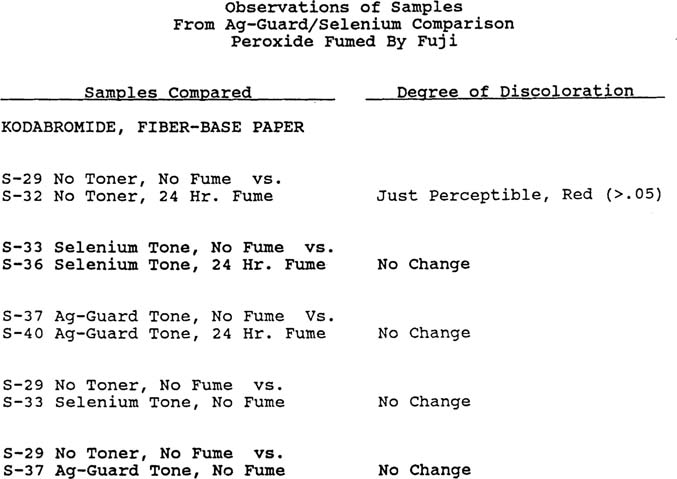

Fig 4: Visual Observation of Kodabromide Paper Samples.

(Based on visual observations made 12/23/86 by Jim Wallace, Lorie Aceto and Joe Goulait under ANSI specified reflected light conditions)

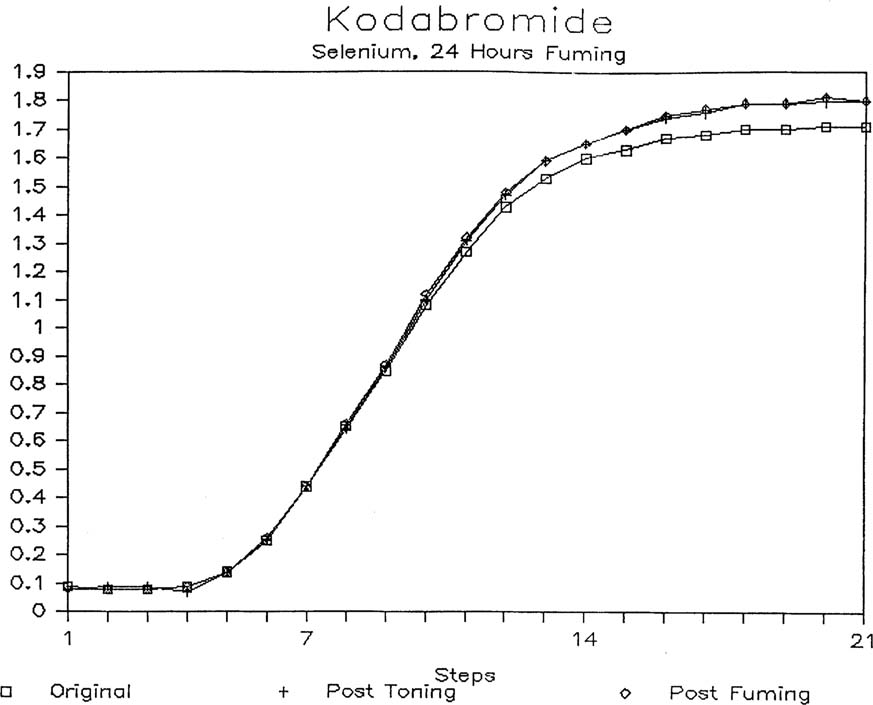

Selenium, read before and after the same treatment also showed no change as a result of fuming. There was, however, an increase in visual density from the middle to top of the scale between readings taken from the original and post toning (Fig 5).

Fig 5: Graph, visual density effect of Selenium on Kodabromide Paper after 24 hours fuming.

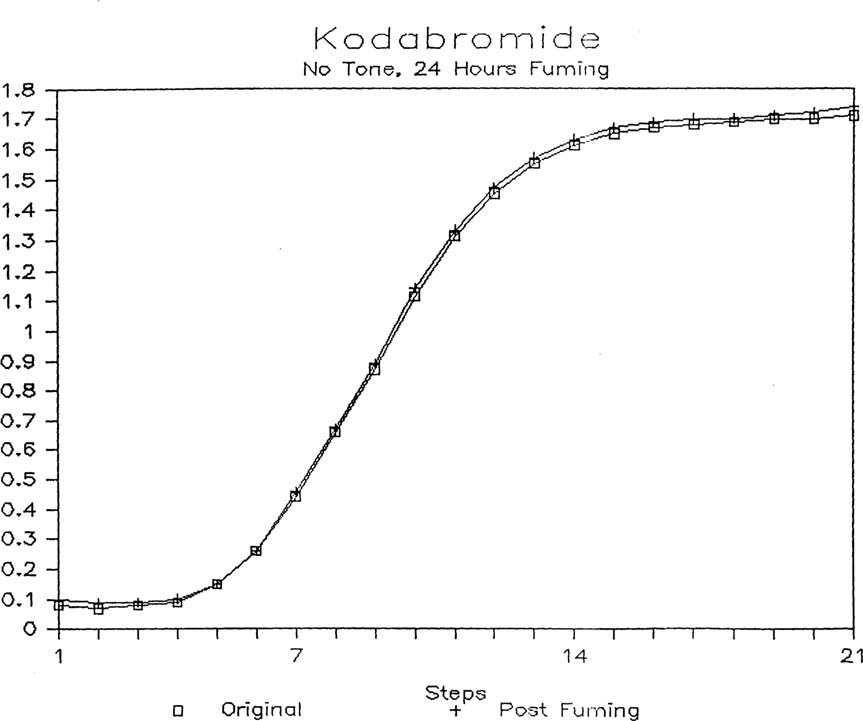

It should be noted that the fiber-based paper which was not toned or post-process treated in any way also showed little or no degradation as a result of 24 hours fuming (Fig 6). In effect, the un-toned and Ag-Guard treated prints displayed less overall change than the selenium toned samples.

Fig 6: Graph, visual density effect of no toning on Kodabromide Paper after 24 hours fuming.

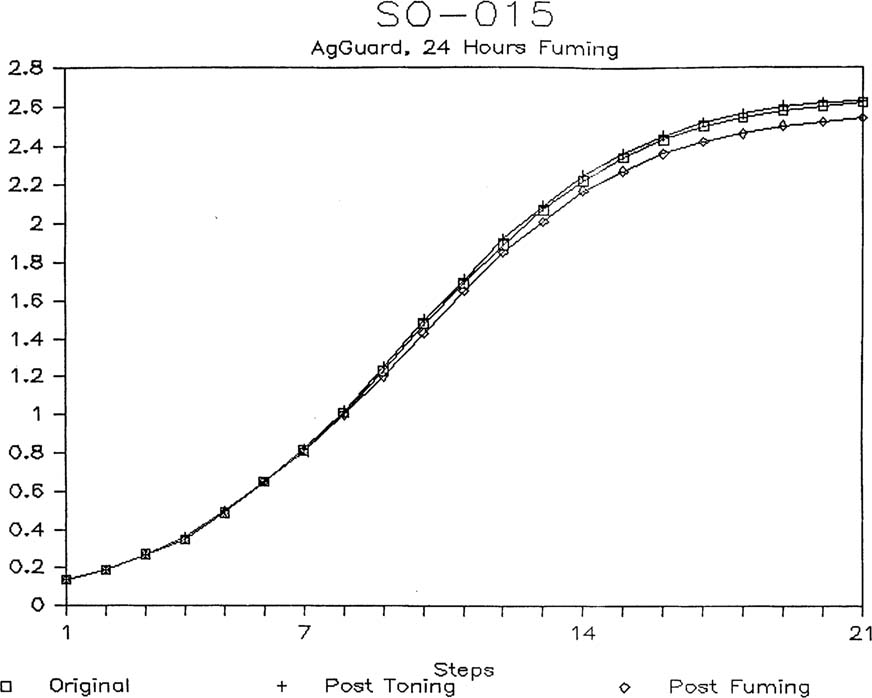

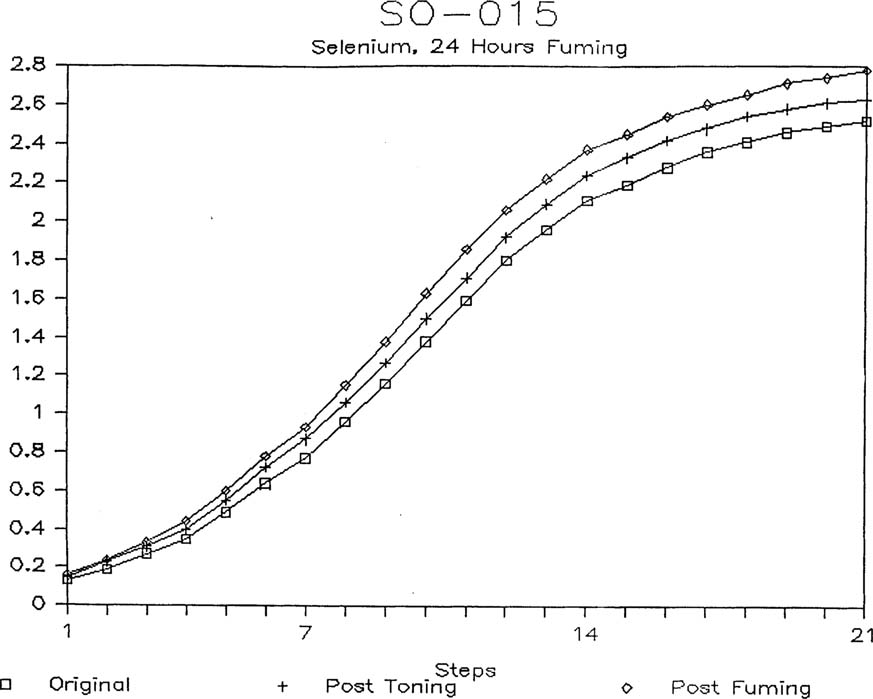

Kodak SO-015 (Direct Duplicating) Film – Very good results were also obtained from Ag-Guard treated SO-015 (Direct Duplicating) film. Visual densities of the Ag-Guard treated sample after 24 hours fuming showed only a slight (-0.10) density loss at the upper end of the scale (Fig 7). This was confirmed by visual observation (Fig 8).

Fig 7: Graph, visual density effect of Ag-Guard on SO-015 Film after 24 hours fuming.

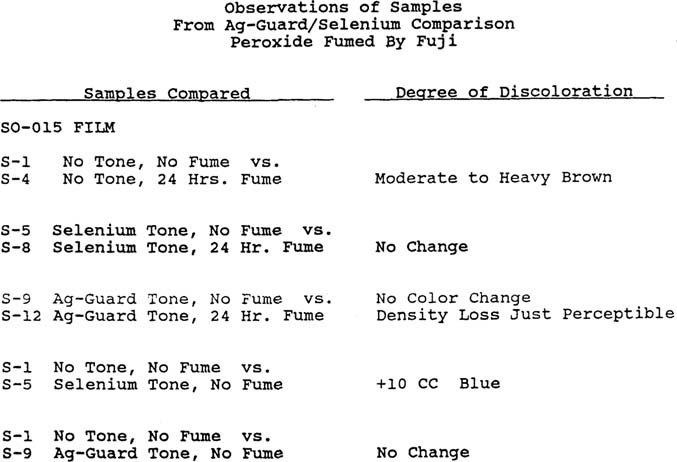

Fig 8: Visual Observation of SO-015 Film Samples.

(Based on visual observations made 12/23/86 by Jim Wallace, Lorie Aceto and Joe Goulait under ANSI specified transmitted light conditions)

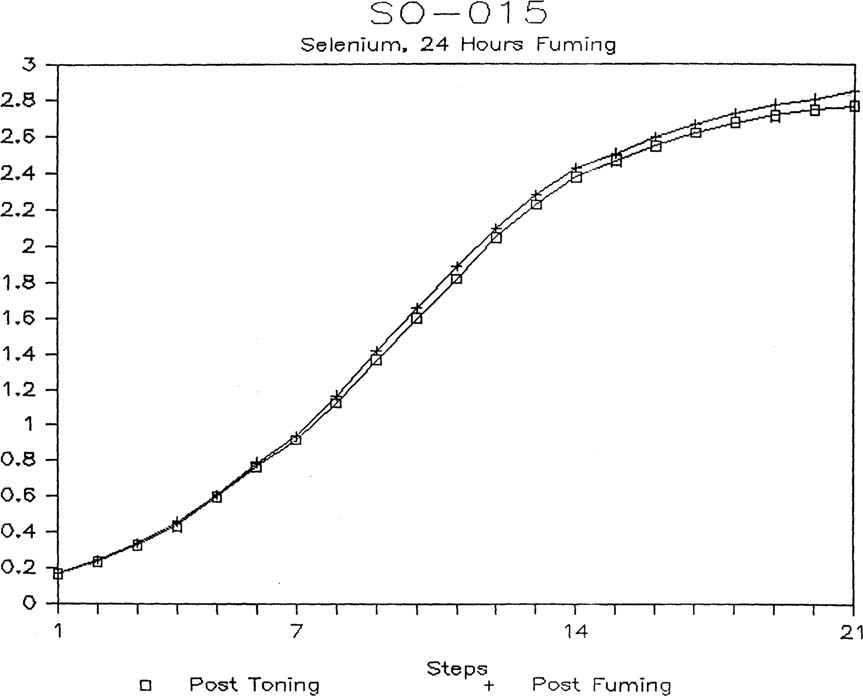

Selenium, read before and after the same fuming displayed a more pronounced change in the form of a density increase. This increase was noted in two steps, post toning (+0.12), and again post fuming (+0.13), with a combined increase of approximately +0.25. (Fig 9) The increase was in overall density, not yellow discoloration as shown in blue density readings (Fig 10). This was confirmed by visual observation (Fig 8).

Fig 9: Graph, visual density effect of selenium on SO-015 Film after 24 hours fuming.

Fig 10: Graph, blue density effect of selenium on SO-015 after 24 hours fuming.

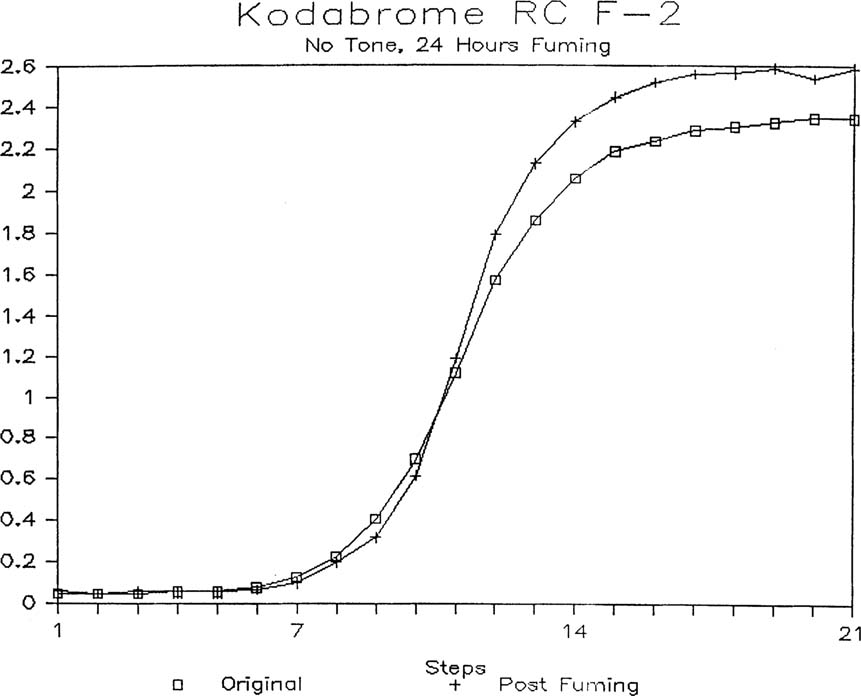

Kodak Kodabrome RC F-2 Paper – Ag-Guard treatment showed little or no effect on the RC paper tested. Following 24 hours fuming, the resulting degradation involved heavy to extensive density and color change (Fig 11). Results were not significantly different from the un-toned sample fumed for the same time (Fig 12). Read for blue density, the Ag-Guard treated sample showed an increase of +0.29 at the upper end, which was approximately that of the un-toned sample. This was confirmed by visual observation (Fig 13).

Fig 11: Graph, blue density effect of Ag-Guard on Kodabrome RD Paper after 24 hours fuming.

Fig 12: Graph, blue density effect of no toning on Kodabrome RC Paper after 24 hours fuming.

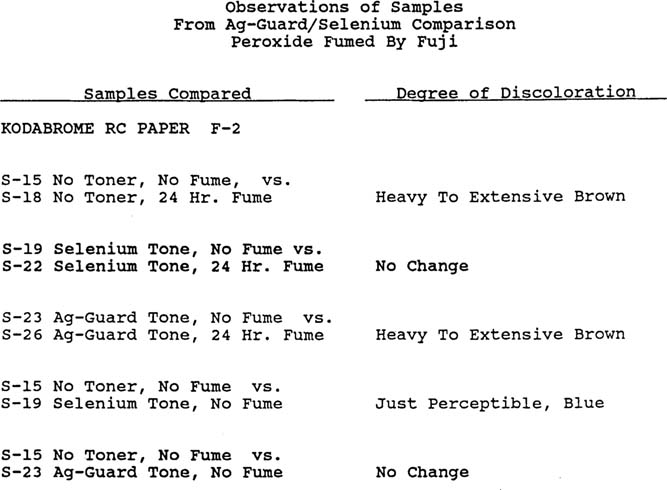

Fig 13: Visual Observation of Kodabrome RC Paper Samples.

(Based on visual observations made 12/23/86 by Jim Wallace, Lorie Aceto and Joe Goulait under ANSI specified reflected light conditions)

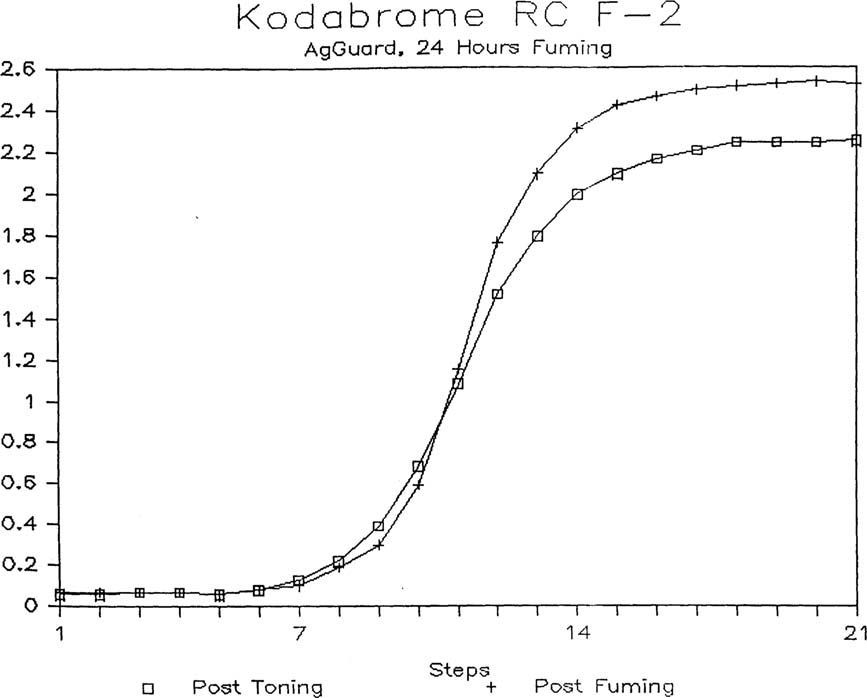

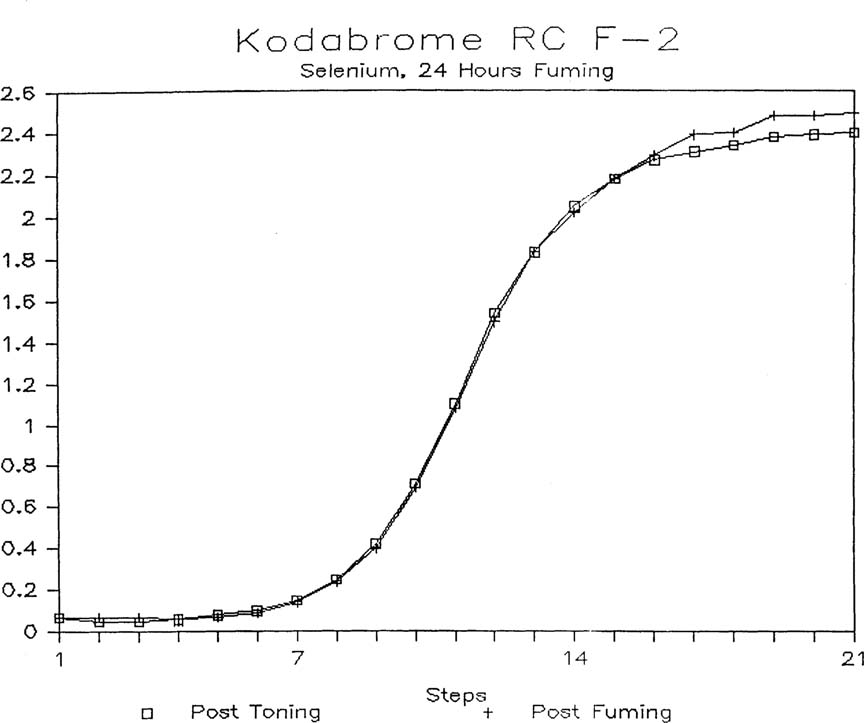

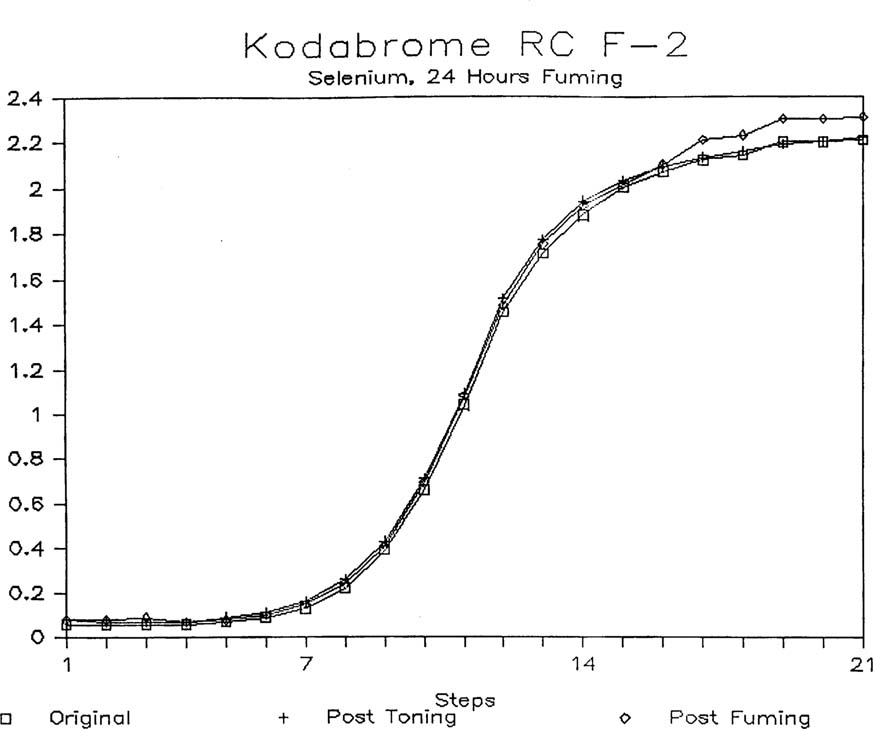

Selenium, read for blue density before and after the same fuming displayed a smaller increase of +0.09 (Fig 14). In the case of the RC paper, there was a barely perceptible change in density between the original and post-toning samples (Fig 15). This was confirmed by visual observation. (Fig 13).

Fig 14: Graph, blue density effect of selenium on Kodabrome RC Paper after 24 hours fuming.

Fig 15: Graph, visual density effect of selenium on Kodabrome RC Paper after 24 hours fuming.

Within the tests conducted, Ag-Guard shows promising potential for extending the life of some photographic products. Because of the variance of results obtained, however, the usefulness of the treatment is believed to be heavily product dependent. (Fuji reports more image stability when Ag-Guard is used with Fuji products.(3)

In the cases where the Ag-Guard proved effective, the overall density changes were less than those resulting from selenium toning. Thus, for those seeking an alternative to selenium because of concern about potentially hazardous materials, Ag-Guard holds promise for some applications.

It should be noted, however, that at present there is no standard hydrogen peroxide fuming procedure. It has been reported by Peter Krause that the Fuji procedure, “seems to give considerably less discoloration than Kodak's, and both yield somewhat different results than obtained by Agfa, Konica and IPC. They all show that RC type paper prints are more susceptible to discoloration than fiber base prints.”(4)

As a result, we believe that further testing on a wider variety of products and using additional fuming techniques is required before definitive recommendations can be made for Ag-Guard beyond the films and papers already tested.

The author wishes to thank Mr. Peter Krause for his guidance at every step of this project. It was at Mr. Krause's original suggestion that an investigation of Ag-Guard was undertaken, and it could not have been completed without his assistance.

Thanks are also due to Dr. Haruhiko Iwano of the Fuji Photo Film Co., Ltd. Dr. Iwano both provided the Ag-Guard chemistry and had the hydrogen peroxide fuming performed on test samples.

In addition, the assistance of Lorie H. Aceto, Deputy Director of the Smithsonian's Office of Printing & Photographic Services is gratefully acknowledged. Ms. Aceto prepared the film and paper samples for this test and performed the hundreds of densitometer readings taken on them during the course of the investigation.

1. Letter, H. Iwano to Peter Krause, September 24, 1986.

2. Drago, F.J. and Lee, W.E. “Review of the Effects of Processing on Image Stability of Black-and-White Silver MAterials” Presented at the Second International Symposium: The Stability and Preservation of PHotographic Images, Society of Photographic Scientists and Engineers, The Public Archives of Canada, Ottawa, August 25–28, 1985.

3. Letter, H. Iwano to Peter Krause, September 24, 1986.

4. Letter, Peter Krause to author, December 31, 1986.

* Presented: Photographic Materials Group, The American Institute For Conservation, Seventh Annual Winter Meeting, New Orleans, Louisiana, February 7, 1987