Topics in Photographic Preservation 1989, Volume 3, Article 13 (pp. 92-111)

The effectiveness of various toning solutions on silver halide emulsions has been investigated. The particular effectiveness of Kodak Brown Toner was noted. Procedures included the use of a test chamber designed by The Image Permanence Institute for hydrogen peroxide fuming. The simplicity and consistency of the apparatus was noted.

“Deterioration is far more frequently the result of defective or careless working than an inherent weakness of the process.”1

Written in the 1911 edition of Cassell's Cyclopaedia of Photography, these words have been the focus for the photographic technician in attempting to achieve the permanence of negative materials. Continuing further, the same heading reads, “A properly fixed and washed negative should be permanent…”2

One need only read the title of Ellen McCrady's History of Consternation Over Redox Blemishes,3 written in April 1983, to realize other elements are at work in the deterioration of silver images. The problem of redox blemishes, overall discoloration, and image fading all still seem to be with us despite the best efforts of the concerned photographic worker.

Turning again to the world of 1911, under the heading “Fading, Causes of,” Cassell notes, “Everyone knows how prone silver in the form of spoons and forks or ornaments, is to tarnish…it can be well understood how much more readily the metal in a finely divided state can be attacked.”4

Silver, “in a finely divided state,” is one description of film, and its susceptibility to tarnish. For one of the causes of this tarnishing reaction under the section “Deterioration,” Cassell adds, “…everyone knows that the minute quantities of sulphur contained in a London fog will tarnish silver articles…”5 Here then, stated 78 years ago as common knowledge, are problems regarding the fragility of the silver image, and a source of attack to that image other than improper washing or fixation. That other source is atmospheric pollutants.

The increased presence of pollutants in the environment has accelerated the need to look for solutions for use in the protective treatment of silver images. Such treatments are also needed for already existing images to enhance their resistance to these pollutants.

In their paper Review of the Effects of Processing on the Image Stability of Black and White Silver Materials, Lee and Drago recommended the use of a toner treatment to, “increase the stability of the silver image towards most forms of degradation.”6 It is interesting that in a sense their recommendation returns us to the recommendations of the past.

Once again under “Permanency” The Cyclopaedia of Photography states, “A sulphide toned bromide print should be as enduring as any photographic print, silver sulphide being a most stable substance.”7 Here is also seen the use of toners as a means of permanency, and in particular the use of a sulfide toner for maximum stability. It should be noted that the recommendation given here is for prints not negatives. The objection to sulfide toning of a negative would be then, as now, a change in its color and density.

In 1984, Fuji Photo Film Co., Ltd. introduced a new toner product called Fuji Ag-Guard. This was a sulphur based toner claimed to produce excellent image stability with no change in image color or contrast. In 1986, Jim Wallace, Director of the Smithsonian's Office of Printing and Photographic Services tested Fuji Ag-Guard toner compared to the effectiveness of selenium toner on a variety of photographic materials. In his conclusions Wallace stated, “Ag-Guard shows promising potential for extending the life of some photographic products. Because of the variance of results obtained, however, the usefulness of the product is believed to be heavily product dependent.”8 He also goes on to say, “It should be noted, however, that at present there is no standard hydrogen peroxide fuming procedure.”9 It was also noted that various manufacturers' test procedures had yielded differing results.

Peroxide fuming and the exposure of photographic materials to oxidizing gases has been carried on since the 1850's as a means of observing the effects of these gasses, but no standard technique has been developed. Eastman Kodak and other manufacturers have been seeking such a standardized test. In July 1987, the Image Permanence Institute (IPI), working under a grant from the New York State Library Preservation Grant Program, began research which had as one of its goals “to develop an improved hydrogen peroxide accelerated test for image oxidation…”10 By May 1988, IPI was able to announce that this objective had been, “met in full.”

It was the development of their test procedures and associated test equipment, as well as conclusions relating to the effectiveness of sulfiding treatments, which led the Smithsonian to re-evaluate and expand the Ag-Guard testing using the IPI test chamber and procedure. Also included in this new testing was an additional sulfide toner treatment, Kodak Brown Toner.

A series of experiments were designed to test a variety of films using Ag-Guard, Selenium, and Kodak Brown Toner treatments. Together with untoned samples, the test film was hydrogen peroxide fumed using the IPI test chamber and recommended procedure.

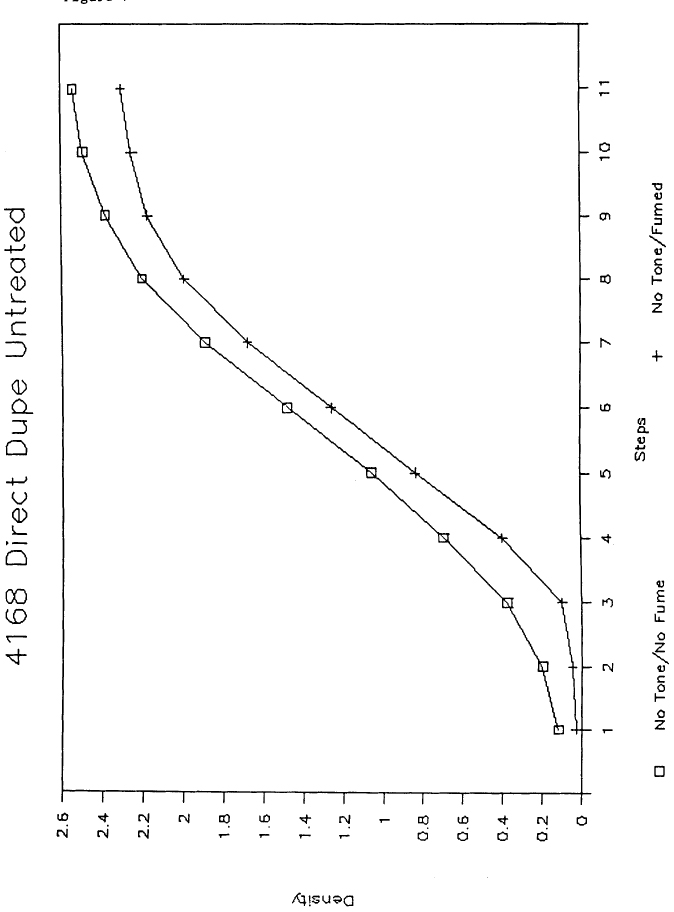

Films Tested were Kodak Tmax 100 and Kodak Professional B/W Direct Duplicating Film. Both films were exposed using a Kodak Step Tablet 1A (11 step) and processed in a Hope 134 B&W processor. Six strips were exposed, processed, toned and fumed for each test.

Toning Solutions used, their preparation, and the treatment procedures were:

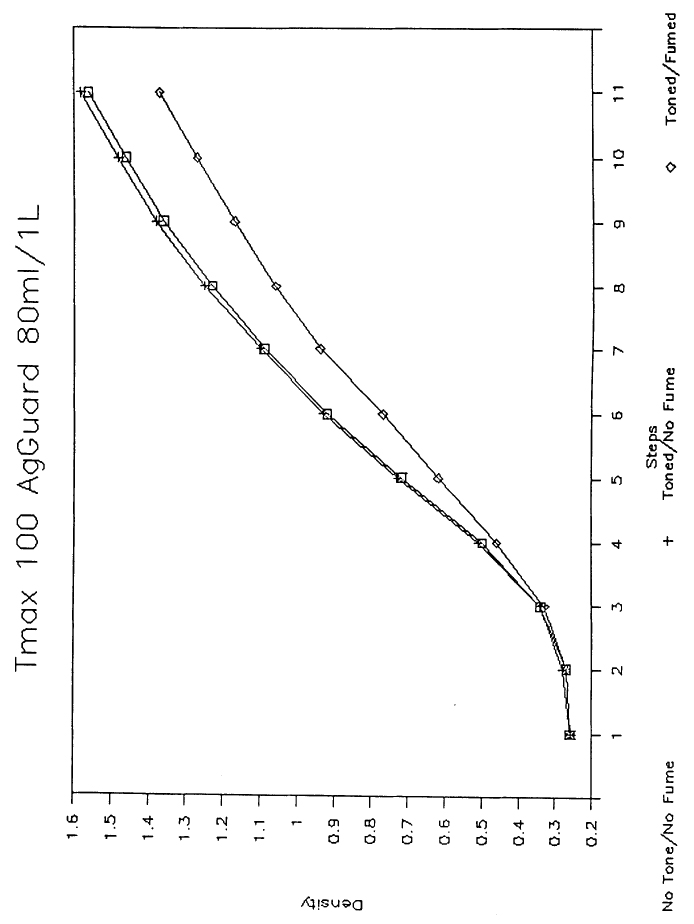

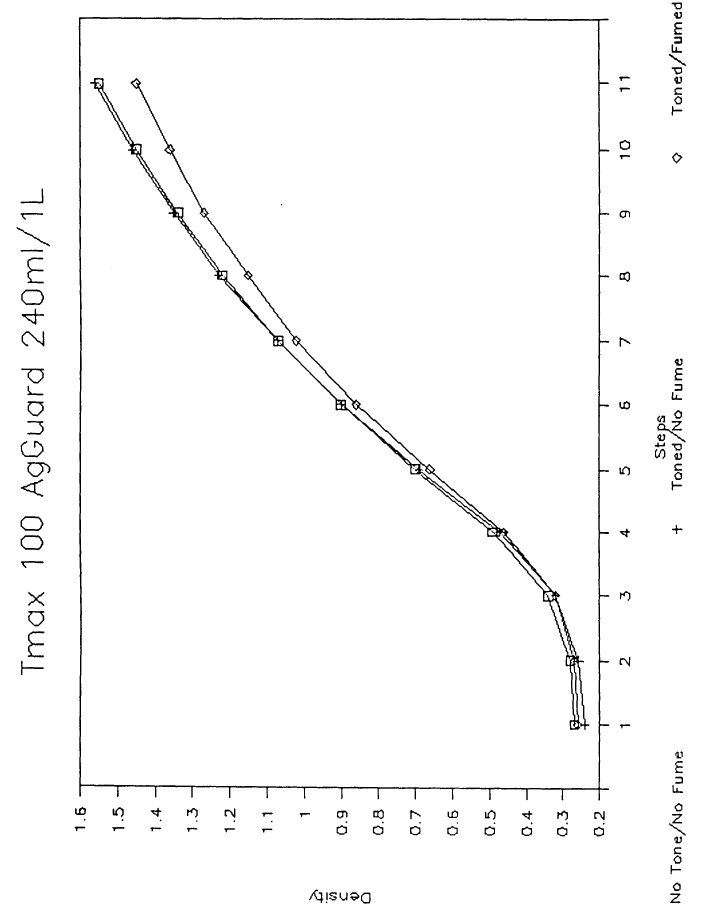

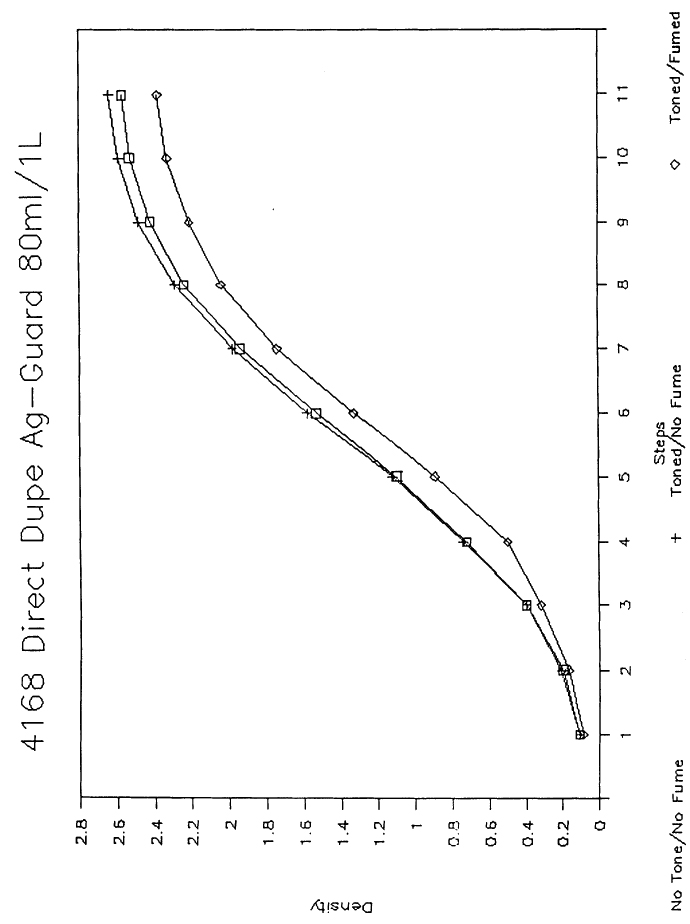

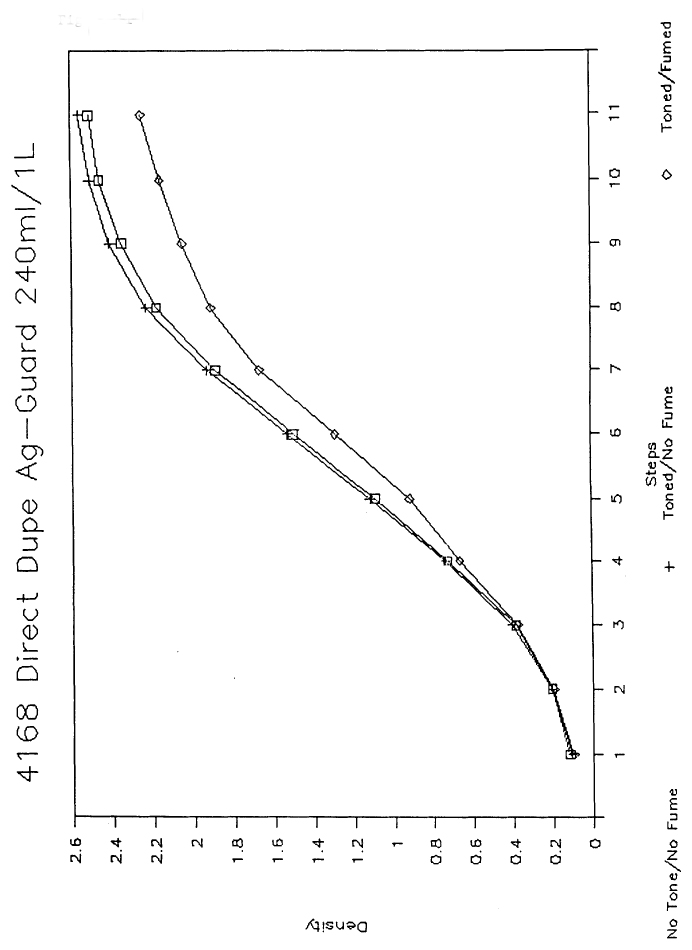

Ag-Guard - In consultation with IPI, two dilutions of Ag-Guard were tested, 80 ml of concentrate in 1 liter of water, and 240 ml to a liter of water. The recommended treatment was for two minutes at 70 F, with no wash.

Selenium - The solution tested was prepared 1 part Kodak Rapid Selenium Toner to 19 parts water. Treatment was for two minutes, followed by a two minute wash at 70F.

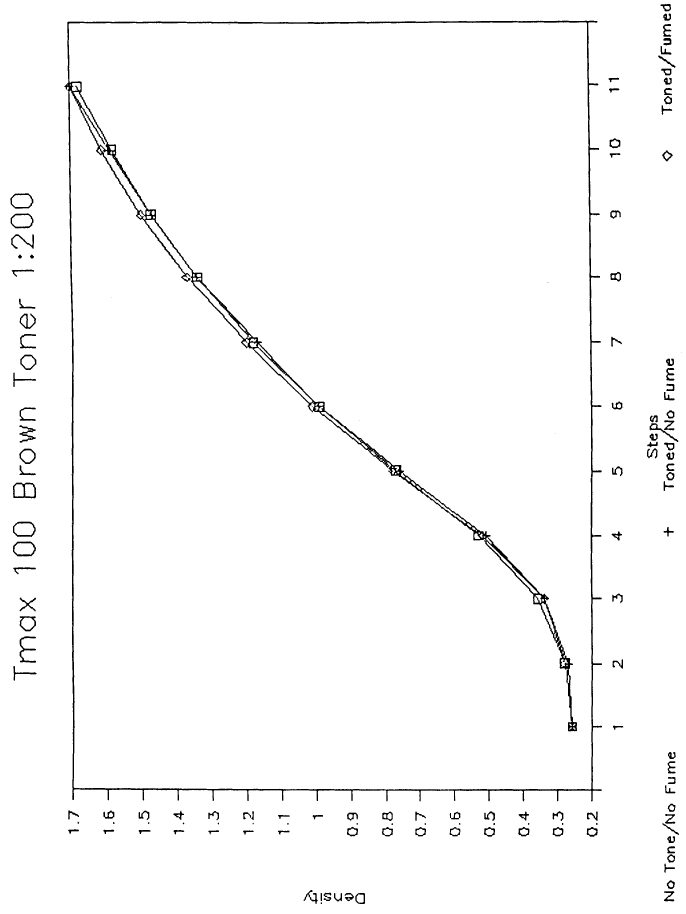

Kodak Brown Toner - The solution tested was prepared 1 part Brown Toner to 200 parts water. Treatment was for two minutes followed by a two minute wash.

Hydrogen Peroxide Treatment following toning was accomplished using the test chamber designed by IPI. Two of the IPI test chambers were purchased by the Smithsonian for use in these tests and future projects. The fuming procedure, as recommended by IPI, called for exposure for a period of 18 hours at 50C and approximately 81% RH. Relative humidity was maintained through the use of a saturated Potassium Chloride solution. Temperature was maintained in a Hotpack Model 434304 chamber. More complete details of the IPI procedure are contained in Appendex 12.

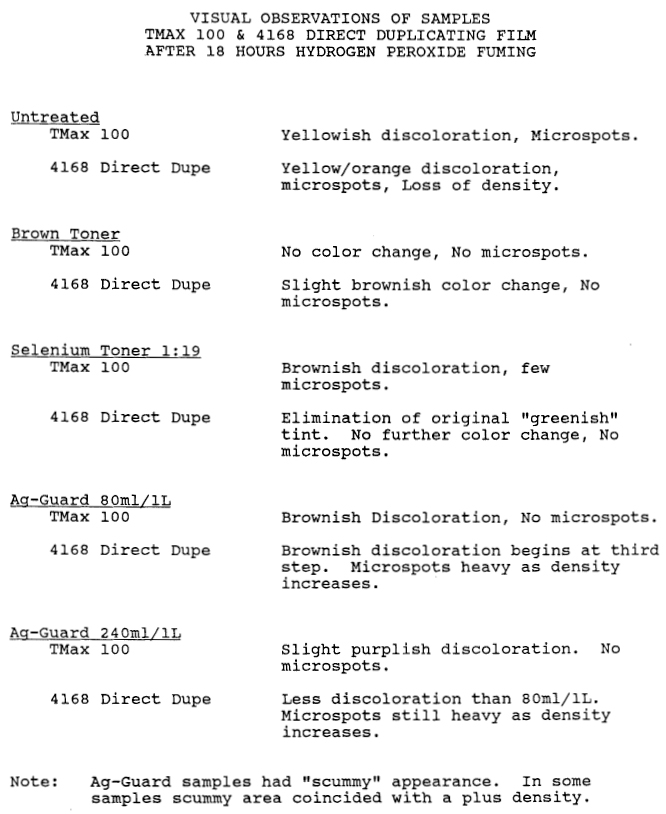

Evaluation of the results were performed both visually and through densitometer readings.

Visual Reference was performed by observing the presence of spots or blemishes which had formed during the fuming process. These observations were made using a Wild M3Z microscope at a magnification of 10X.

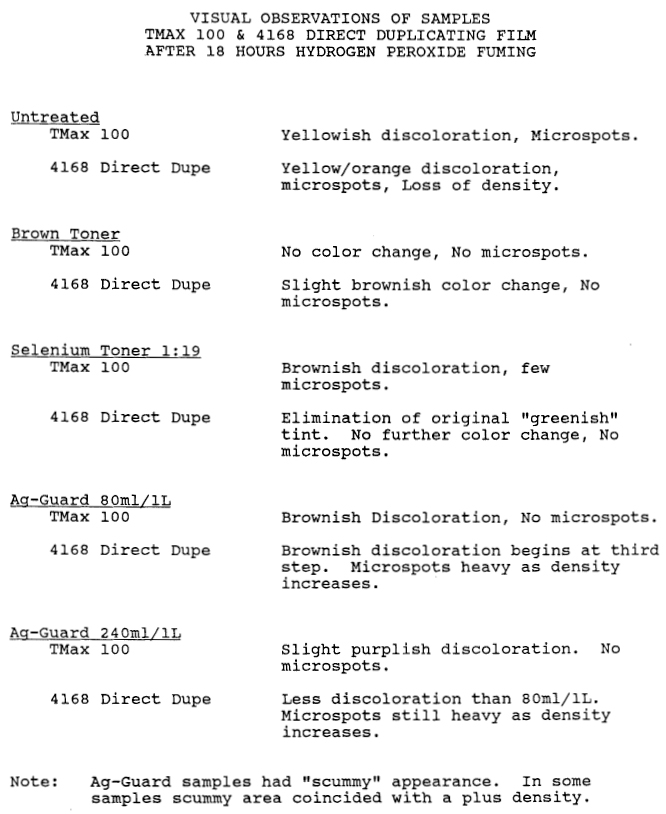

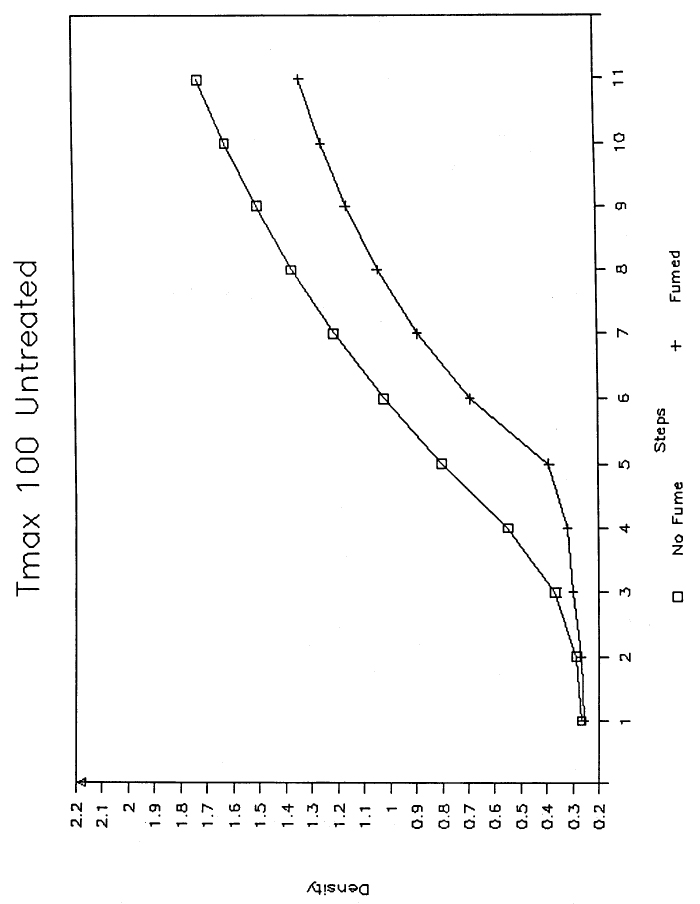

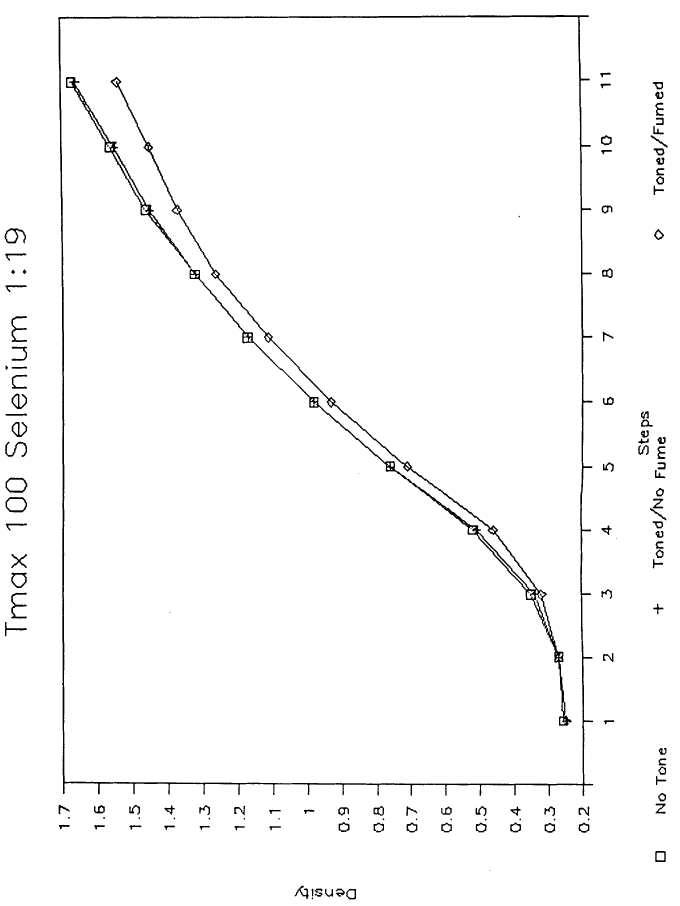

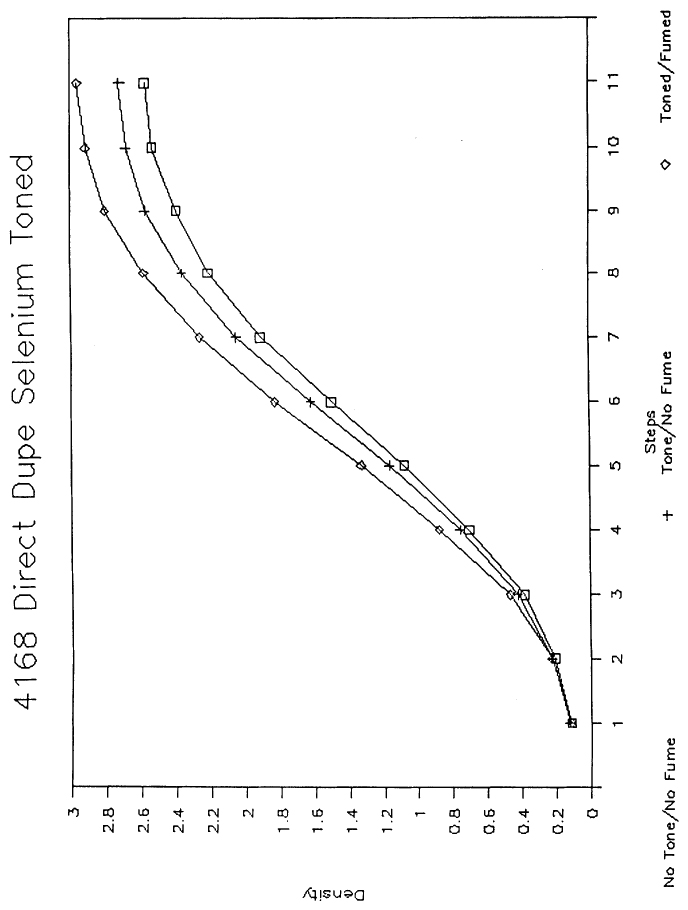

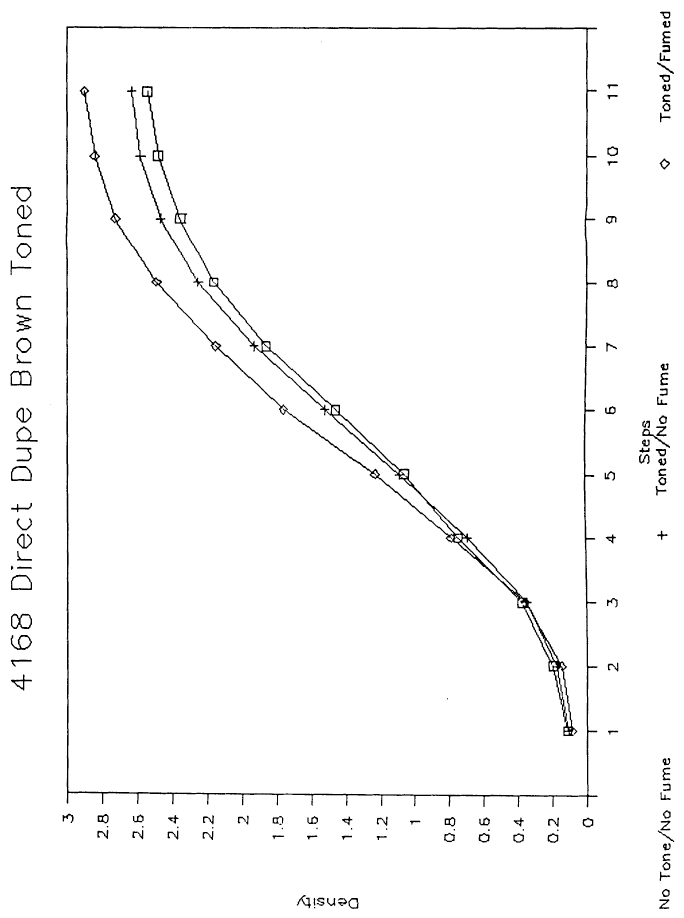

Densitometer Readings were made from each of the 11 steps of all six strips used in each test. The results were then averaged and those values used to create the attached graphs. A complete series of readings were made after the film was processed, after toning, and again after fuming. In each case, readings were made using a Macbeth TD504 densitometer, through the Status “A” red filter.

Readings were also made of D-Min, D-Mid, and D-Max values using Status “A” Visual Density (green), and Blue Density filters.

Procedures - The post-fuming samples obtained from the IPI test chambers showed even distribution of exposure to the hydrogen peroxide gas, and good consistency of results.

Selenium showed some protection to the TMax film, but some red spots and discoloration were present. Selenium showed almost complete protection when used with the Direct Duplicating Film.

Ag-Guard at the dilution of 240ml to 1 liter, offered approximately equal protection to TMax film as that found with Selenium. At the weaker dilution of 80ml to 1 liter, noticeably less protection was observed. Ag-Guard used at the 240ml dilution on Direct Duplicating Film showed less discoloration than the 80ml dilution, however, both samples showed heavy red spots.

Brown Toner provided almost complete protection to TMax film. Results showed almost no discoloration or red spot formation. Brown Toner when used with the Direct Duplicating Film prevented the formation of red spots, however, some noticeably overall discoloration of the film was observed.

The IPI test chambers and the accompanying recommended procedures were able to be used with a minimum of training. Good consistency of results and even fuming were especially notable. The use of two chambers operating in the Hotpack unit creates many possibilities for flexible future testing.

The author gratefully thanks Dr. Peter Krause for his generous assistance in the preparation of this paper.

Thanks are also due to Jim Reilly and the staff of IPI for their help in familiarizing me with the peroxide fuming procedures using the IPI test chamber.

I would also like to thank Jim Wallace of the Smithsonian for his encouragement in this project.

Bernard Edward Jones, Editor, Cassell's Cyclopedia of Photography, Cassell Publishers, 1911, London, New York.

ibid.

Ellen McCrady, “History of Consternation Over Redox Blemishes”, unpublished manuscript, April, 1983.

op. cit., Cassell

op. cit., Cassell

Drago and Lee, “Review of the Effects of Processing on the Image Stability Stability of Black and White Materials”, given at Public Archives of Canada, Aug. 25–28, 1985, Ottawa, Ont. Canada, pg 63.

op. cit., Cassell

Jim Wallace, “An Examination of the Effectiveness of Ag-Guard Protecting Silver Halide Photographic Emulsions”, presented Feb 7, 1987, AIC/PMG Seventh Annual Winter Meeting, New Orleans, La.

ibid.

Reilly, Nishimura, Cupriks, and Adelstein, “Stability of Black and White Photographic Images With Special Reference To Microfilm”, presented to Conservations In Archives Symposium, National Archives of Canada, May 1988, Ottawa, Ont. Canada.

Observations of Samples of TMax and 4168 Direct Duplicating Films After 18 Hr. Hydrogen Peroxide Fuming.

Graph, TMax 100, Untreated.

Graph, TMax 100, Selenium 1:19.

Graph, TMax 100, Brown Toner, 1:200.

Graph, TMAX 100, Ag-Guard 80ml/1L.

Graph, TMax 100, Ag-Guard 240ml/1L.

Graph, 4168, Untreated.

Graph, 4168, Selenium 1:19.

Graph, 4168, Brown Toner, 1:200.

Graph, 4168, Ag-Guard, 80ml/1L.

Graph, 4168, Ag-Guard, 240ml/1L.

IPI “Procedures for Peroxide Testing”, 2pp.

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12