Topics in Photographic Preservation 2001, Volume 9, Article 6 (pp. 85-96)

The history, technology, and materials of lamination and face-mounting processes for photographs are described and cross-sections of face-mounted prints are shown. Trouble shooting for both techniques are listed, followed by an overview of current and future research.

Since the advent of the medium, photographs have been mounted and presented in many different ways. Modes of presentation and formats of works of art are a good reflection of a culture's aesthetic preferences at any given time. In this manner, the design of a mat or the way a photograph has been mounted can often be a useful clue to the age of an image (Katcher 1978). Since the mid 1980's, new trends have emerged in the world of fine art photography. More and more artists have been exploring the limits of the medium and new ways of displaying their photographic works. Modern works, be they of photographic or digital origin, often have extremely large dimensions, and their handling, exhibition, and preservation can be challenging. Recently, artists have been favoring two finishing techniques for their photographs: plastic lamination and face-mounting to a sheet of clear poly(methyl methacrylate) (PMMA) such as Plexiglas®. The reasons are both functional and aesthetic. Laminating or face-mounting large prints gives them a flatness that cannot be achieved with an unmounted print cornered or hinged in a traditional window mat. It also adds rigidity to the piece and eliminates the need for heavy glazing, thus facilitating handling and lowering the cost of production. Other advantages include protection against ultra-violet (UV) radiation, fingerprints, and air-borne pollutants.

Next to the protection these techniques are designed to offer, the aesthetic aspect is important. Laminates may have many different surface finishes that can alter the original characteristics of the photograph, including the removal of surface glare. Face-mounting consists of applying a hard, thick, transparent, and highly glossy surface to a photographic print, a process that results in a “wet” look, similar to the effect reached by applying varnish to a painting. The similarity of the silicone rubber adhesive, PMMA, and the photographic emulsion in terms of their refractive index, their intimate contact with each other, and the exclusion of air, lead to a minimum of reflection and refraction of light at the interfaces between the materials. In this manner, the scattering of light that would be present in a layer of air between the print surface and the glazing in a conventional frame is eliminated. The original surface of the photographic print cannot be seen, whatever the viewing angle or distance. Instead, light reflects from the surface of the acrylic, behind which is a deep “space” of color, namely the thickness of the PMMA sheeting. In effect, for both glossy laminated and face-mounted prints, the image contrast is heightened, the colors appear darker, and the perceived saturation of the hues is enhanced, resulting in a very brilliant image.

It is these characteristics primarily that have fuelled the popularity of face-mounting chromogenic color prints among artists, especially in Germany and other European countries. In a review of German photographer Matthias Hoch's work, Hans Dieter Huber points out that it is the surface of a print that determines its reception as a work of art. He goes on to remark that “the traditional method of framing a photograph with a passepartout and ordinary glass creates a greater distance to the viewer's eye which is not only perceived spatially, but which may also be apprehended as an emotional, intuitive or semantic distance. The way a photograph is presented - its surface, its materiality and its optical distance - plays a significant part in the specific form of the meaning which then derives from the image” (1998). Interviews with several artists1 who currently use these finishing techniques confirmed this point of view. Nonetheless, when asked about their feelings about the long-term stability of such techniques, all interviewees responded that they suspected the two methods were “not good” for their photographs. Finally, some artists admitted they feel pressured by their galleries to adopt the presentation method that is in fashion today and sells well.

Plastic lamination has been used for commercial purposes since around 1980 and is commonly used to physically protect display prints hung in public spaces. Prior to this date, laminates were mostly used in making tamper-proof drivers' licenses or identification badges (Wilhelm 1993, 152). Laminated photographs are often mounted flush to a rigid support and exhibited without glazing. Artists such as Utah Barth, Matthew Barney, Adam Fuss, and Michal Rovner, among many others, regularly use plastic laminates on their works.

Options for laminating films are endless. Research on the market of plastic laminates for conventional photographs and digital prints revealed more than forty different brands, each offering dozens of films for applications ranging from billboard to floor graphics. Plastic laminates vary in quality and price and fall into five general categories:

The first category consists of films with pressure-sensitive adhesives, also called “cold films” or “cold laminates”, because no heat is required to activate the adhesive. The base of the films most commonly used is made of poly(vinyl chloride) or polyester, but polycarbonate, polypropylene, polyethylene, and Tedlar® bases2 are also available. A release liner protects the surface of the tacky, pressure sensitive, clear acrylic or-copolymer-based adhesive. Cold laminates are offered in a wide variety of surface finishes such as gloss, satin, pebble, luster, and matte. Polyester is more rigid than vinyl and can be made ultra-glossy. Vinyl is softer and comes in more finishes than polyester. In terms of optical clarity, pressure-sensitive laminates are usually of better quality than thermal laminates. They adhere to a broader range of materials and are available with a greater variety of adhesives than the other types of laminate. They can be used on almost any substrate and are preferred particularly for ink jet prints and “difficult” projects. They must be applied with a roller laminator that provides enough constant pressure for the adhesive to bond evenly to the substrate (Figure 1). Pressure-sensitive films cost four to five times more than any other type of film.

Figure 1. Roller laminator at Photobition, Chicago, IL.

These laminates usually consist of a polyester base with a polyethylene adhesive that requires temperatures between 210 and 240d°F for activation. They are applied with hot-shoe-laminators or multi-heat roller laminators (MHL) and do not have a release liner. Standard thermal laminates are much cheaper than the pressure-sensitive films and are appropriate for a wide variety of media (photographs, electrostatic prints, xerographic prints, etc.) but cannot be used with heat-sensitive materials such as wax-based ink jet prints or coated media. Polyethylene adhesives do not show extensive penetration. In some instances, when used with certain types of ink jet prints, the adhesive will bond to the top layer of the deposited ink instead of bonding to the paper substrate. As a result, the laminate may peel away from the paper, thereby also removing the ink. Polyethylene may also not adhere to ink jet inks with incorporated glycerin.

These products are relatively new but professionals in the field of photo-finishing foresee that they will eventually replace the previous group due to the problems faced with standard thermal films when laminating ink jet prints with high ink coverage (IRgA 1999, 410). Although they have the same components as standard thermal laminates, they need lower temperatures (185–210°F) for bonding and are slightly more expensive.

This category consists of a hybrid type of laminate. These films have a somewhat pressure-sensitive adhesive, necessitating a release liner, but they also require an elevated temperature of around 170–195°F to fully activate the adhesive. They are most often made of a vinyl film coated with a thermoplastic copolymer adhesive that shows high penetration and, when used with ink jet prints, can bond through the ink to the paper support, even in areas of high ink coverage. Heat-set laminates conform perfectly to the surface topography of the substrate as they lack rigidity, a characteristic which may not be desirable. They are also more expensive than the purely thermal laminates.

Although often described as akin to the film-based laminates, liquid laminates are the result of a different technology and can be compared with print lacquers. They are either solvent or water-based and are becoming very popular because of their low price: up to eight times cheaper than a quality film laminate. They can be applied to the substrate in a variety of ways and are mostly used with electrostatic prints. They bond chemically to the image and do not delaminate, and they provide good moisture and UV protection. Fade resistance is increased with incorporated hindered amine light stabilizers (HALS) that act as free-radical scavengers.3 Liquid laminates also provide a good protection against oxidants, and manufacturers claim that they will not yellow over time.

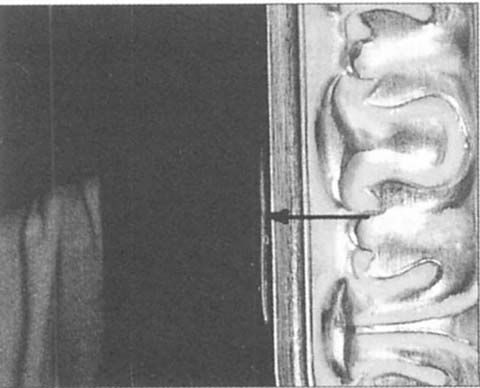

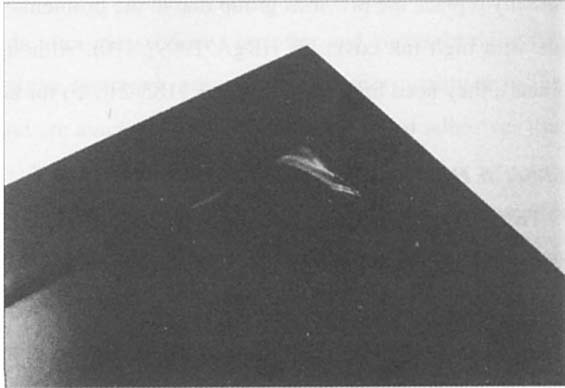

During and after a lamination procedure, a number of problems and flaws can become apparent. Working areas must be absolutely clean, as dust and other particles easily get trapped under the film in the lamination process. The variables of importance during laminating are temperature, speed of operation, nib pressure,4 hardness of the cylinder surface, and tension on the web.5 High moisture content in the print (of particular concern with ink jet prints), insufficient paper tension, or insufficient laminating temperature can cause waves in prints. Improper cooling following the application of a thermal laminate may also contribute to the formation of waves. Small bubbles, cloudy colors, silvering,6 and stains on the prints are induced by incorrect lamination speed, improper cylinder temperature, and/or inadequate nib pressure. Oil from fingerprints on the print surfacemay also contribute to areas of poor adhesion. The curling of a photograph after it has been laminated can be caused by an excessive film to print thickness ratio, insufficient or excessive web tension, or inadequate temperature of the upper or lower cylinder. Blistering of ink jet prints occurs when ink or paper coatings are off-gassing. This problem has been observed when the temperature is too high and/or when the cylinder speed is too slow. Delamination along the edges is another common problem (Figure 2), especially for prints that are mounted flush to their secondary support. Yellowing and deformation of plastic laminates over time has been observed in many instances (Figure 3).

Figure 2. Delamination along the edge.

Figure 3. Deformation of aging laminate.

Face-mounting has been a favorite finishing and presentation method for contemporary European photographers for about fifteen years. Two categories of materials are available to face-mount a photograph to a sheet of clear acrylic: pressure-sensitive adhesive films and silicone rubber and primer systems, often referred to as “Diasec mounting” (Figure 4).

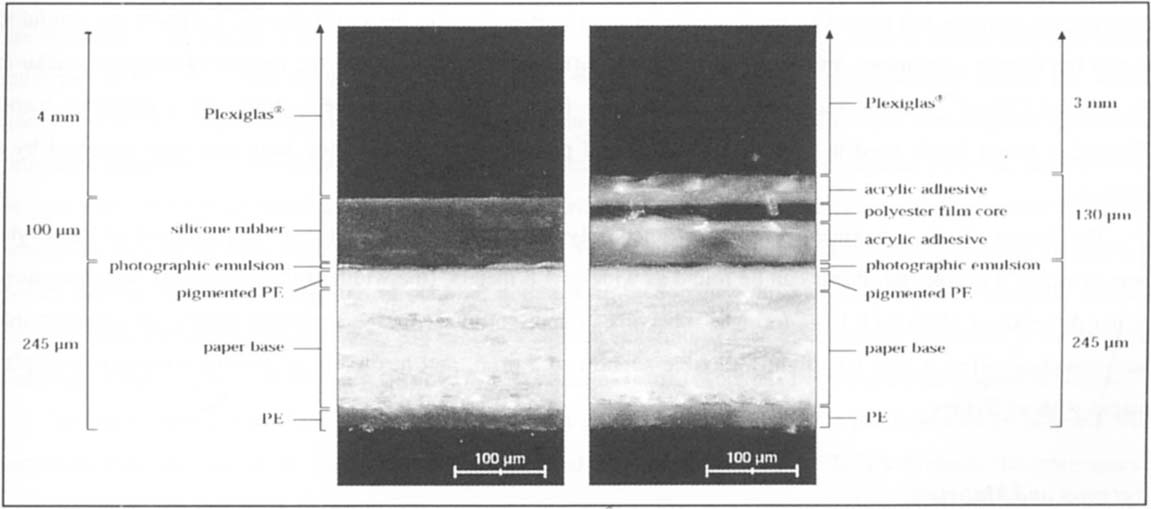

Figure 4. Cross-sections of face-mounted photographs. Left: Diasec® silicone rubber; Right: double-sided adhesive film.

Only a few companies offer pressure-sensitive adhesives for face-mounting and the choice is more limited than that for lamination films. The adhesive is usually acrylic-based, and most manufacturers offer acid-free options. The films can have a clear plastic, usually polyester carrier between two exterior layers of adhesive, but unsupported films of adhesive are also available. Mounting studios seem to prefer double-sided adhesive films, but the reason why they do so is not clear. The film is applied between the photograph and the acrylic sheet between two cylinders under high pressure. At present, pressure-sensitive adhesives are mainly used for face-mounting photographs for advertising and trade fair design, but the material is also gaining popularity in the fine art photography sector, as the results are visually indistinguishable from prints face-mounted with silicone rubber, and the process is often less expensive.

In the late 1960's and early 1970's, Heinz Sovilla-Brulhart, of Switzerland, put considerable effort into developing mounting methods that would not only serve to preserve a photograph but also make it presentable (Jürgens 2001; Pénichon 2000). In 1971, he applied for a patent for his newly developed process, given the name Diasec®, of using a moisture-curing silicone rubber as an adhesive between the photographic emulsion of a print and a sheet of clear acrylic (Sovilla-Brulhart 1974). License contracts with strict regulations have been sold to a small number of mounting studios throughout the world, and the Diasec® process has always been highly secretive. The licensed mounting studios, of which there are ten worldwide, are found in Austria, Belgium, England, France, Germany, Holland, Israel, Italy, and Switzerland. In December 1992, Heinz Sovilla-Brulhart died, and his widow and son took over sales of the license, production, and distribution of the special primer, the solution that enhances adhesion between the silicone rubber, the acrylic sheet, and the emulsion. The ingredients of the primer are the main secret of the Diasec® process, and Mrs. Sovilla referred to the recipe as her “Coca-Cola formula”. The silicone rubber is produced by an undisclosed German company to which the licensees are directed.7

Since the use of Diasec® face-mounting has increased greatly over the past ten years, a number of unlicensed photographic printing and mounting studios have begun to offer virtually the same process, but most are careful to respect the license agreements and are selling it under different names. Although the results may appear similar to the original Diasec® process, the materials used come from other manufacturers. Although a protected name, “Diasec” is being freely used to describe face-mounted photographs, even if they have not been mounted by a licensee.

The format of a face-mounted print is restricted only by the size of the photographic paper and of the acrylic sheet to which it is adhered. Prints can be found as wide as 1.8 meters8 (the width of the paper roll), with lengths of greater dimensions. With such large formats, it becomes important to secure the structural stability of a photograph. Face-mounting offers a stiff but slightly flexible support to a print, and has led to a growing tendency to display images without frames.

When a photograph is laminated or face-mounted, the photographic emulsion is essentially sealed in an airless environment that should not harm it chemically and should protect it from the surrounding environment. The main advantage of silicone rubber over conventional adhesives is that the curing process occurs spontaneously in the air-tight space between the print and the acrylic sheet by utilizing the moisture present in the gelatin emulsion of the photograph. The dehydration and insulation that thus occurs lowers the number of O2 and H2O molecules available to produce ozone and peroxide during the degradation process triggered by UV radiation (Sovilla-Brulhart 1970). However, the sealing of a color print in such a laminate structure may not be completely beneficial. Residual chemicals in a poorly processed print and acetic acid from the curing process may be trapped in a face-mounted print, and the complete elimination of air penetration to a color emulsion may increase the rate of cyan dye fading (Kodak Professional Division 1998; Aono et al. 1982).9 At the present state of knowledge, the face-mounting process is considered irreversible.

The silicone rubber commonly used in face-mounting processes is a one-part room temperature vulcanizing (RTV) material that is available as an uncured polymeric compound in an airtight container. Upon exposure to air, its main component, poly(dimethyl siloxane), cures rapidly with the help of atmospheric moisture, thereby releasing acetic acid, giving it its classification as an acetoxy RTV sealant.10 There is minimal or no shrinkage in this process. The cured material is a rubbery, permanently flexible, chemically stable and inert substance that exhibits release properties.11 Due to its relatively pure and simple make-up, it is for the most part bio-compatible and non-hazardous to humans. It is also known as a material that can withstand great changes in temperature and relative humidity and age without yellowing. Silicone rubber formulations typically include a polymeric backbone (60–80%), a cross-linking agent (1–5%), a reinforcing filler (10–30%), and processing aids (1–5%).12 Sealants used in face-mounting photographs have no incorporated pigmentation, and are thus colorless and transparent.

Most silicone rubbers are used in conjunction with a primer that is designed to enhance the adhesion between the rubber and the materials to which it is applied. A primer is often of a chemical structure similar to the adhesive it is designated for, but it is applied in a solution of a much greater dilution and lower viscosity (Brewis 1983, 242–243). Primers used in silicone rubber face-mounting contain organo-functional silicones or silane compounds that are delivered in an organic solvent mixture. The solvents provide for a low surface tension vehicle that will wet the substrate surface well and displace adsorbed air and water vapor, which would otherwise hinder the viscous adhesive from coming into intimate contact with the adherent. As hybrid molecules with both organic and silicone functions, organosilane compounds are able to form primary bonds with both the organic adherent, the PMMA or gelatin, and the silicone-based adhesive. Instead of having to bond with the surface of the adherent, the sealant adheres mainly to the thin coat of primer (Cook 1970, 60), which thus acts in a mediating fashion. In short, the primer interacts both chemically and physically, in that it firstly enhances primary bonding, and secondly enhances the efficiency of bonding by providing the adhesive and the substrate with a material that is similar in composition. Each face-mounting system utilizes a specific primer or set of primers that has been chosen for a specific sealant.

Sovilla's original patent did not specify the kind of acrylic sheet to which the prints should be adhered. Most mounting labs use sheets of PMMA with incorporated UV stabilizers. The PMMA protects the photographic emulsion from UV radiation, abrasion, and mechanical damage. The necessity for UV filters is not absolutely clear, however, as most color papers since the 1980's have been manufactured with a protective UV filtering surface coating (Wilhelm 1993, 111, 145). It may more likely be the capacity of PMMA to absorb a portion of the visible light that is of importance here.

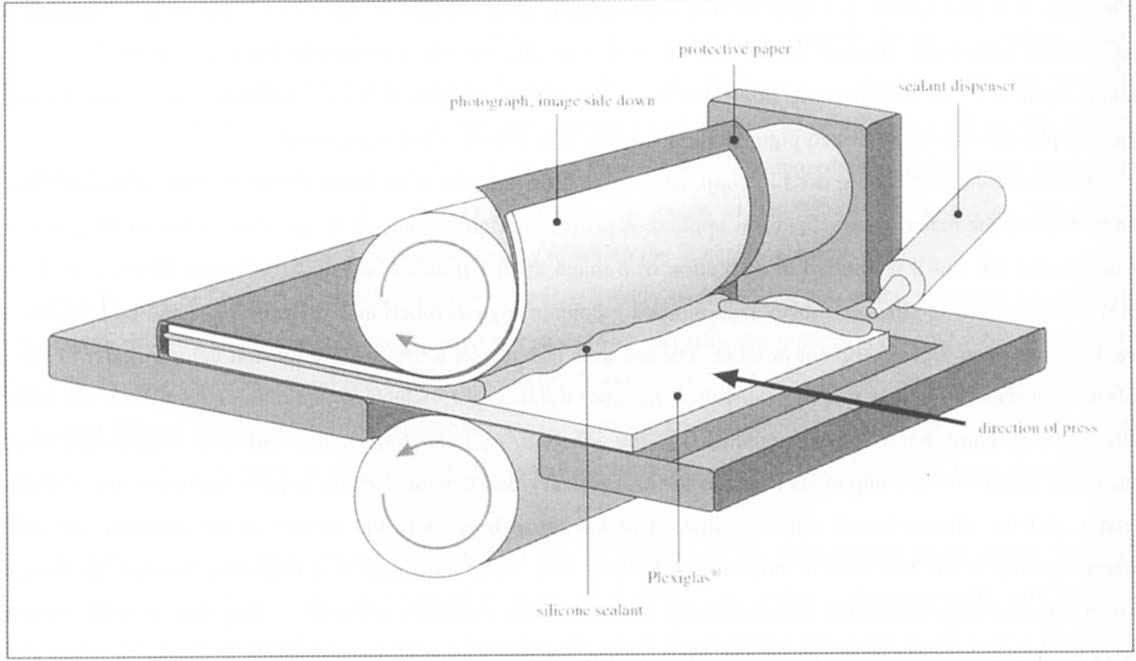

Face-mounting with silicone rubber requires a large, double-cylinder press (Figure 5). Prior to mounting, the primer is usually applied to the surfaces of both the PMMA and the photograph, and the solvents are allowed to evaporate. On large prints, the primer is only applied to the border areas of both PMMA and print for economical reasons. The print is placed face down onto the PMMA and one of the short edges is taped around the equivalent edge of the PMMA to form a hinge. With the taped edge butting up against the slit between the cylinders, the print is lifted up and draped over the top cylinder. Silicone rubber is dispensed uniformly at the nib to form a line across the PMMA. The package is then automatically pulled through the electric press, whereby the print is firmly pressed onto the PMMA and the silicone rubber is evenly and thinly squeezed out between the two materials to form a film. Should the line of silicone at the nib become too thin, extra sealant may be dispensed. The silicone rubber is left to cure for 48 hours.

Figure 5. Cut-through schematic of the cylinder press face-mounting technique using silicone rubber sealant

Early face-mounted photographs were simply inserted into a wooden frame that left the back of the photographic print unprotected. In more recent years, German mounting studios have resorted to protecting the verso of the face-mounted print by adding a 1–2 mm poly(vinyl chloride) (PVC) hard foam sheet with double-sided pressure sensitive adhesive film in another press.

Certain problems pertaining to the mounting process have been noted sporadically at mounting studios. A localized or overall formation of yellow-magenta stains, ranging from slight to vivid, can form on a print. These stains do not seem to appear at a later point if they have not already formed after 48 hours. Studio technicians have noted that the staining occurs more frequently when there is high relative humidity in the mounting room, especially in the summer.13 One suggested cause given by the mounting technicians is poor processing of the photographic print, resulting in the presence of chemical residues. In addition to local staining, shifts of the image hue toward magenta and overall fading have been observed. These changes can appear after three to five days or as late as two weeks after mounting. The cause presumed by the mounting technicians is the dissolution of the topmost emulsion dye layer, namely cyan, a theory that remains to be examined. Although some indications have been found that might explain these problems, it is clear that much research must yet be completed to understand the causes and mechanisms of the staining.

A slight graduated staining of the white borders around the exposed print area has also troubled one studio, as if colors have bled from the image area to the non-image area. This phenomenon can be observed in all face-mounted prints with a white margin, however, and may be an optical effect of internal reflections of light between the top and bottom edges of the PMMA. It may also be due to migration of dye by solvent. Further mounting problems include non-uniform adhesion of the print to the PMMA, resulting in delamination at the corners, and, as with lamination, the inclusion of dust and other particles between the emulsion and the PMMA. The main problem connected with face-mounting seems to be that of the susceptibility of the PMMA surface to abrasion and scratching, as well as its tendency to build up static charge and attract dust, both properties which make it extremely hard to transport and clean.

The preliminary investigation into the two finishing techniques described above focused on studying the materials and techniques involved as well as the basic structure of the finished products. Considering their widespread and increasing use in today's fine art photography and in the advertising industry, in-depth research into their long-term stability is certainly called for. Experiments were carried out at the facilities of the Image Permanence Institute in Rochester, NY, and, under the supervision of Prof. Alison Murray, at Queen's University in Kingston, Ontario. A number of laminated and face-mounted photographs were subjected to accelerated light and dark aging tests following procedures described in ANSI/NAPM IT9.9–1996. In addition, samples from three laboratories, which use different sets of silicone sealant and primer as well as double-sided adhesive film, were subjected to an analysis of their physical structure by examination of cross-sections with a microscope, a comparison of FT-IR spectra of the primers and sealants, and quantification of acetic acid off-gassing by gas chromatography. The results are currently being evaluated and will be presented at the IIC 19th International Congress in Baltimore, Maryland.14

Both lamination and face-mounting are techniques that harbor unknowns with respect to the conservation of the materials involved. An investigation into the adhesion mechanisms, both physical and chemical in nature, would provide insight into the potential problems associated with laminate objects such as differing expansion and contraction coefficients and reactions to fluctuating environmental conditions. In terms of the longevity of the adhesive, manufacturers have demonstrated that silicone rubbers are very stable materials. Independent tests would, however, serve to better examine the aging characteristics of these adhesives.

It is unknown how laminated and face-mounted photographs react to changes in RH and to direct contact with water, but it would seem that the edges are the weak point of the system. It might be beneficial to determine the rate at which water vapor is taken up and given off by the materials involved. It is assumed that laminated and face-mounted prints are not as susceptible to mold damage as unfinished prints, as the most nutritious material, the gelatin, is sealed in an airtight environment.

A further topic for future study of the face-mounting processes would be possible short and long-term effects of the solvents contained in the primer. It would also be of interest to examine the use of so-called neutral or non-corrosive curing sealants as an alternative to those that give off acetic acid. An alkoxy material cures with atmospheric moisture by releasing methanol and ammonia. The presence of an alcohol may, however, lead to crazing of the PMMA, especially if it is an extruded sheet that contains internal stresses. The influence, if any, of acetic acid on the gelatin and the dyes and colour couplers of the emulsion might be examined. An Oddy test with silicone rubber face-mounted prints might give more insight into issues of acid retention and off-gassing.

Guidelines specifically for handling and exhibiting laminated and face-mounted prints may have already been established in institutional collections. Visitors at an exhibition might not be aware that a laminate or the PMMA surface of a framed face-mounted print is an integral part of the object, and may inadvertently touch the surface without realising that they are actually touching the object and not just the glazing that is there to protect the work of art. Cold storage, as commonly used for color prints, should be evaluated for potential negative effects in the long-term preservation of laminated and face-mounted images.

In terms of conservation and treatment options, little experience has yet been gathered and published. For face-mounted prints, dirty, scratched, and damaged PMMA may be one of the greatest problems faced by conservators, as even simple cleaning and dusting can lead to further surface abrasion. For both finishing techniques, further experimentation will be necessary for devising methods of in-filling and in-painting losses in the photographic emulsion that have occurred by deep scratches to the unprotected print verso. Since cases of delamination have been observed, the development of methods for re-adhering the layers will also be of importance.

The proposed topics for future research compiled here should be regarded as a list of possible approaches to gaining a better understanding of the permanence and conservation of laminated and face-mounted photographs. It would benefit from further input and experimentation, with the goal that, in the near future, laminated and face-mounted prints become objects we feel comfortable about handling, exhibiting, storing, and treating.

1 Telephone interviews were realized between January and March 2000, directly with the artists or through the intermediacy of their assistants or gallery.

2 Tedlar® is a polyvinyl fluoride (PVF) film that was introduced in the 1960s by DuPontTM. According to the manufacturer, “Tedlar® PVF products have unique properties that include excellent resistance to weathering, outstanding mechanical properties, and inertness towards a wide variety of chemicals, solvents and staining agents. Tedlar® PVF products are available in a wide variety of films and in a resin form”, from the DuPont website <http://www.dupontcom/tedlar/products/">.

3 An interesting property of these additives is that they are not consumed by the scavenging reaction so they have long life times in the plastics.

4 The nib is the line where the two laminating rollers meet and lamination takes place (IRgA 1999, 422).

5 A web is the unwinding width of plastic coming off a supply roll, or the continuous flow of laminate coming out the back of the laminator (IRgA 1999, 422).

6 The term “silvering” is used by the trade to designate small bubbles in the finished print that disrupt the colors and give the image a silvery look.

7 Personal communication with Jean-Marc Trimolet, owner of Diasec JMT, Cossonayville, Switzerland, and Mrs. Sovilla, February 8, 2001.

8 Even wider prints can be made by adhering strips of photographic paper along the edges of the image to create white margins.

9 Aono et. al. conducted a series of experiments that confirmed that oxygen insulation accelerates cyan fading while improving the stability of both magenta and yellow dyes. It was also found that oxygen can easily penetrate through the back of the paper, and that cyan stability is not affected when the back and the edges of the laminated photograph are not sealed.

10 Though less common, alkoxy sealants can also be used. These release ammonia and methanol during the curing process.

11 Other silicone compounds such as silanes are applied to paper and polyester sheets to form silicone release materials.

12 The percentages given relate to the composition of GE Silicones sealant SCS 1200 (GE Silicones 1998).

13 Personal communication with Dieter Jung, Manager, Grieger Düsseldorf, August 2000.

14 1–6 September 2002, Title: “Works of Art on Paper, Books, Documents and Photographs: Techniques and Conservation”.

Aono, T., K. Nakamura and N. Furutachi. 1982. The effect of oxygen insulation on the stability of image dyes of a color photographic print and the behavior of alkylhydroquinones as antioxidants. Journal of Applied Photographic Engineering 8 (5): 227–231.

Brewis, D. M. 1983. Aluminium adherends. In Durability of structural adhesives, ed. A. J. Kinloch. London: Applied Science Publishers. 215–254.

Carlton, A. 1997. Mounting and laminating survey 97. Modern Reprographic, April 1997. Also available at www.modrepro.com/pages/issues/1998/97-04/cover.html

Cook, J.P. 1970. Construction sealants and adhesives. New York: Wiley Interscience, John Wiley & Sons, Inc.

G. E. Silicones. 1998. Material safety data sheet: SCS 1201 RTV silicone rubber compound. November 6, 1998. www.gesilicones.com

Huber, H. D. 1998/99. Matthias Hoch - To the beat of the techno-systems. In Matthias Hoch - Speicher. Dogenhaus Galerie Leipzig, Goethe Institut Paris. Exhibition catalogue without page numbering. Also available at <www.hgb-leipzig.de/ARTNINE/huber/writings/hoche.html">

International Reprographic Association (IrgA). 1999. Mounting and laminating equipment and materials - Buyers guide. Oak Brook, IL: International Reprographic Association.

Jürgens, M. C. 2001. Silicone rubber face mounting of photographs to poly(methyl methacrylate): process, structure, materials, and long-term dark stability. Kingston, Ontario: Queen's University.

Katcher, P. 1978. How to date an image from its mat. Photographic Society of America Journal. 44 (August): 26.

Kodak Professional Division 1998. Effects of post-processing treatments on the image stability of color prints. Kodak Publication No. E-176. Rochester, NY: Eastman Kodak Company.

Modern Reprographic. 1998. Reprographic industry study. Modern Reprographic, July 1998. Also available at <http://www.modrepro.com/98-07/study06.html">

Pénichon, S. 2000. Chronology and description of patents for face-mounting photographs. Unpublished report. Chicago: The Art Institute of Chicago.

Sovilla-Brulhart, H. 1974. Procédé de collage de tirages photographiques. Confédération Suisse: Bureau fédéral de la propriété intellectuelle. Patent 546 968 delivered on January 31, 1974.

Sovilla-Brulhart, H. 1970. Panneau-support d'un tirage photographique. Confédération Suisse: Bureau fédéral de la propriété intellectuelle. Patent 489 040 delivered on April 15, 1970.

Wilhelm, H. and C. Brower. 1993. The permanence and care of color photographs: traditional and digital color prints, color negatives, slides, and motion pictures. Grinnell, IA: Preservation Publishing Company.

The authors wish to thank the Andrew W. Mellon Foundation and the German Academic Exchange Service (DAAD) for their support in this research project, the Art Institute of Chicago, Dieter Jung (Grieger Düsseldorf), Nora Kennedy, Prof. Alison Murray (Queen's University, Kingston, ON), Douglas Nishimura, Photobition Chicago, Doug Severson, Mrs. Sovilla, and Jean-Marc Trimolet (Diasec JMT).