Topics in Photographic Preservation 2011, Volume 14, Article 35 (pp. 206-226)

Presented at the 2011 PMG Winter Meeting in Ottawa, Canada

This paper was published in Scanning: The Journal of Scanning Microscopies, vol. 32, 122-133 (2010), and is reprinted with permission from Wiley Periodicals, Inc.

Summary: Surface metrology techniques that are non-perturbing (non-contact, non-invasive and non-destructive) are well suited to in situ surface studies of historical and fine art photographs. They allow for the quantitative examination of the microstructure of the photograph surface, thereby, offering an important advancement in the examination, documentation, and characterization of silver gelatin photographs and other modern and/or historic imaging materials. This paper presents the application of an optical confocal scanning disc microscopy system to the qualitative and quantitative characterization and assessment of a silver gelatin photographic paper, Ilford Glossy, submitted to different humidification and flattening protocols.

Surfaces, the two-dimensional outer boundary between the three-dimensional object and its environment, have many attributes and are perceived as the complex interplay of three factors: surrounding illumination, surface optical properties such as reflection, and surface geometry or topography (Motoyoshi et al 2007). Photographs have been generated using a wide range of materials such as silver and gold metal for daguerreotypes, egg proteins for albumins, cellulose nitrate for collodions, acacia gum for gum prints and gelatin for silver gelatin prints. In addition to the material variety, a multitude of surface types were made available. Silver gelatin photographic papers since their beginning have had generous ranges of styles categorized by features such as texture, gloss (also referred to as brilliance), basis weight and color or tint (Kodak 1977; Funderburk 2007).

Interest in the characteristics and nature of the surface of photographic papers is growing in both conservation and curatorial circles. To date few studies on these surfaces have been pursued for lack of instrumentation that will provide valuable, practical and useful information. The surface characteristics of photographs can be used to identify the nature of the materials used and its process of manufacture. For example, albumin based photographs have a distinguishing surface feature that consists of small elongated cracks parallel to the machine direction of the paper. Swan (1981) noted that there appeared to be an increase in the number of cracks on albumin photographic image surfaces after aqueous treatments. To quantify Swan’s observations, Messier & Vitale (1994) studied the further development of cracks after aqueous surface and immersion treatments. Passafiume (2001) prepared a sample book of the types of silver gelatin developed out papers used by the well known American photographer Edward Weston (1886-1958). The instrumental technique of edge reflection analysis (ERA) was developed to study silver gelatin surface topography (Arney et al. 2002). It was used to study surface changes in silver gelatin prints subjected to various humidification, wetting and flattening regimens to qualitatively demonstrate that these various procedures irreversibly alter gelatin surfaces and the degree and type of alteration as a function of the differing procedures. The quantitative aspect of edge reflection analysis was, unfortunately, not informative (Chen 2003). The above studies are a demonstration of a desire to objectify and quantify the surface characteristics of photographic papers, and especially the resulting nature of conservation treatment interventions.

This paper introduces the conservation of art and cultural heritage communities to the field of surface metrology, specifically that of optical surface metrology, through the study of silver gelatin photographic papers surfaces. It demonstrates how well suited surface metrology is to the qualitative and quantitative study of photographic paper surfaces and its potential to other areas of cultural heritage preservation and conservation, and it would appear to fulfill the unstated desire for quantification of observed surface changes expressed in earlier studies.

Advances in electronics, optics and faster computing in the past decade have revolutionized the fields of 2D contact surface profilometry and 3D optical and surface metrology. The antiquated surface metrology contact methodologies, which have the potential to irreversibly perturb surfaces, were never seriously considered by cultural heritage institutions and although still useful in industry are quickly becoming a tool of the past. New optical surface metrology tools such as confocal scanning disc microscopy systems use light to probe surfaces rapidly and risk-free, and yield a wealth of areal data unachievable with 2D contact methods. Such instrumentation would appear to be ideally suited to enable in-situ non-perturbing (non-contact, non-destructive and non-invasive) examination of delicate and sensitive surfaces of the wide range of historic and artistic works encompassing the cultural heritage accumulated by mankind. The new non-perturbing instrumentation presents new approaches and possibilities for collection-based studies, which were heretofore impossible (Ravines, P., Wiegandt, R., and Wichern, CM. 2008; Ravines et al. 2008; Sotiropoulo and Wei 2006; Wei et al. 2005; Grynszpan et al. 2004).

This paper presents the application of confocal scanning disc microscopy to the characterization and monitoring study of a single silver gelatin photographic paper treated with various humidification and flattening regimens.

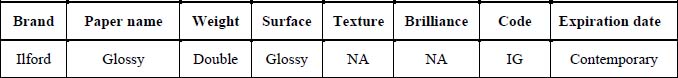

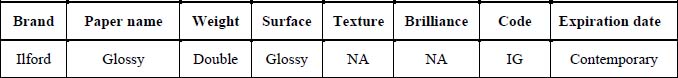

The contemporary silver gelatin photographic paper studied was an Ilford Glossy double weight paper, details listed in Table 1.

Table 1: Ilford Glossy silver gelatin photographic paper description

Full sheets (8 x 10 or 11 x 14 inches) of the Ilford Glossy photographic paper were fully exposed with overhead illumination for 30 seconds to achieve maximum density and processed using freshly made developing solutions by two different methods. Group A paper samples were developed using Kodak Dektol Developer for 90 seconds; Kodak stop bath, 15 to 30 seconds; Kodak Rapid fixer, 8 minutes; final running water wash of 40 minutes; squeegeed face down, and dried on racks face up. Group B was developed similarly but the Kodak Rapid Fixer fixing bath contained a gelatin hardener. The hardener is not specified but is likely to be aluminium sulfate (Kodak MSDS 1990; Neblette 1962). All papers were then trimmed to 4 x 5 inch samples.

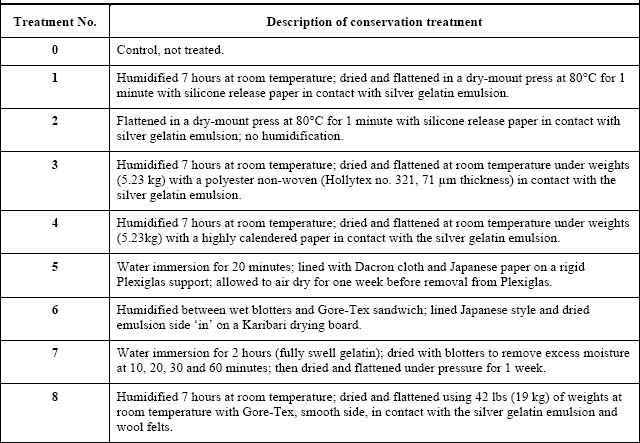

The Ilford Glossy photographic paper samples were subjected to all the different humidification, wetting and flattening treatment protocols listed in Table 2.

Table 2: Humidification, wetting and flattening experimental protocols applied to both Non-hardened (group A) and Hardened (group B) prints

Observation of surface changes of the control and treated photographic papers were monitored with the µsurf optical 3D measurement system. Three to five measurements of random locations on each of the 4 x 5 inch treated papers were made for all papers.

In this research a NanoFocus (NanoFocus AG, Lindnerstrasse 98, D-46149 Oberhausen, Germany, info@nanofocus.de) µsurf optical 3D measurement system based on confocal scanning disc principle was used with a 20x objective. Data acquired from the µsurf only provides information on the geometry and physical structure of a surface and not its chemical composition. The confocal system provides 3D surface data arrays of 512 x 512 points for all objectives, represented graphically by contour and isometric maps. A 20x objective with a numerical aperture (NA) of 0.60 and a working distance (WD) of 0.9 mm provided an 800 x 800 µm2 measurement field with a vertical resolution of 4 nm was used to examine the photographic papers in this study. In surface metrology it is standard practice and acceptable to measure one sampling area alone (Stout 2004, 98). In this study three to five different areas on each photographic paper sample were examined and average results are presented. µsoft software version 6.1 was used for operation of the confocal topometer and data acquisition. µsoft Analysis Standard software version 5.0 was used for pre-processing data, data analysis and calculation of ISO 25178 surface height parameters: root-mean-square height (RMS), Sq, and arithmetic mean height, Sa, of the surface. Pre-processing consisted of leveling, the removal of linear trends from the recorded data due to the misalignment of nominal surface plane and the data collection datum (Stout 2000, 8). Filtering used a robust Gaussian filter of 80 µm, ideally suited for smoothing feature rich surfaces, which provides in one filtering procedure both roughness and waviness surfaces simultaneously. Leveled and filtered data results are presented as contour and isometric views/plots, and surface roughness and waviness height parameters are listed in tables.

The surface characterization of the Ilford Glossy silver gelatin photographic papers of both non-hardened (group A) and hardened (group B) groups and monitoring results of surface changes effected by humidification, wetting and flattening regimens are presented.

The Ilford Glossy paper is described to have smooth texture, least surface topography, and highest brilliance or gloss, Table 1. The terminology to describe the surface characteristics of photographic papers is elusive. For many years Kodak used ‘texture’ and ‘brilliance’ to define and organize their papers in their Professional Darkroom Dataguides (Kodak 1977). A recent study proposes the use of ‘surface texture’ and ‘surface sheen’ instead of brilliance, where ‘surface sheen’ is the light reflected off the paper’s surface (Dune et al. 2006). The graphicsatlas web site borrows from the above study and continues use of the terms ‘texture’, as Kodak has, and ‘sheen’ (www.graphicsatlas.org accessed 12/2008). It is interesting to note that photographers were unusually adept at using the wide range of black-and-white-paper terms available for choosing papers to provide the ‘look’ of their final print. For example, glossy, or high sheen, papers provide highest contrast. Although these terms have been used for decades by industry and photographers alike, they are wanting. Application of surface metrology, topographical and tribological principles to study surface features of photographic papers are viable and complementary approaches that can further visual analysis and provide valuable quantitative information.

Surface geometry has three main quantifiable features: roughness, waviness and form (Whitehouse 2002; Stout 2004, 130). Surface roughness is defined as the finest irregularities (shortest wavelength or highest frequency) of a surface resulting from a production process or material condition; it is represented by roughness height parameters such as the root-meansquare height, Sq, and the arithmetic mean height, Sa. Depending on the surface type, its roughness can be at the micrometer and/or nanometer level. Waviness includes the more widely spaced deviations (longer wavelengths or lower frequencies) of a surface from its nominal shape and is intermediate in wavelength between roughness and form. Waviness height parameters, similar to roughness height parameters, are root-mean-square height, Sq, and arithmetic mean height, Sa, (ISO 25178; Whitehouse 2002). These new metrics have been used to characterize the Ilford Glossy silver gelatin photographic paper surface, establish baseline information, and evaluate surface changes and alterations due to treatment effects. To start, a control sample of the glossy paper has been visually and quantitatively described with 3D (xyz) arrays of areal data and statistically analyzed. 3D views and surface metrics greatly complement each other.

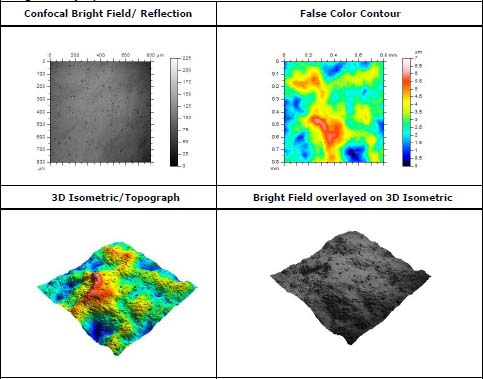

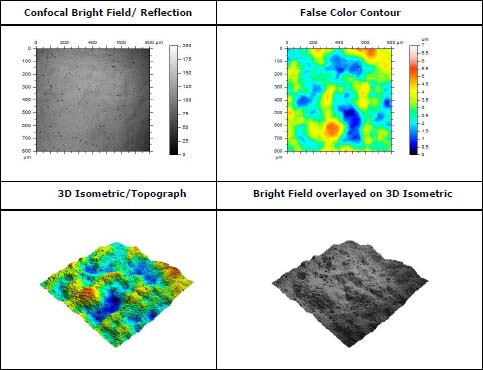

The Ilford Glossy paper developed without hardener, group A, is displayed in Figure 1. Each column presents different views of the photographic paper area measuring 800 x 800 µm2. The first column shows a black and white fully focused bright field specular image (also referred to as a reflection view) generated by stacking the confocal slices. In this case and because of the flatness of the photographic paper samples this view would be the equivalent of an epiilluminated bright field view from a standard optical/compound microscope with a 20x objective.

The second through fourth columns show the various ways the 3D arrays of areal data collected from the confocal scanning disc microscope can be displayed. The second column shows a contour plot of the 3D data in false color where the blues indicate depths, greens and yellows mid range, and reds and whites peak elevations. The third column displays false color 3D isometric plots where surface roughness, short wavelength features, and waviness, longer wavelength features, are clearly observed. The fourth column shows the black and white bright field images overlaid onto 3D isometric topographs. The overall vertical range (z-depth) of the false color contour plot and both sets of 3D isometric views is from 0 to 7 µm.

In column one Figure 1, the specular black and white view represents the optical/reflection properties of the gelatin surface, and the Ilford Glossy paper shows a smooth glossy surface peppered with small pits or pores. The false color contour and 3D isometric views in columns 2 and 3 expand the limited range of information provided by the 2D specular black and white image. The contour and 3D views confirm the Ilford Glossy pits and smooth glossy low textured surface.

As mentioned earlier, the optical properties are distinct and separate phenomena from the topography of the gelatin surface. The black and white bright field/reflection image overlaid over the 3D topograph, column 4, provides an instructive comparison on the nature of surface features due to surface geometry and reflection; it allows for the visual distinction between topographical and optical/reflection properties.

The false color contour and 3D isometric plots, and black and white overlaid onto 3D isometric plot fully complement the specular bright field images providing more information, improving visual analysis of physical and topographical features, which can be measured, expanded and highlighted, and differentiated from optical phenomena.

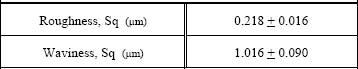

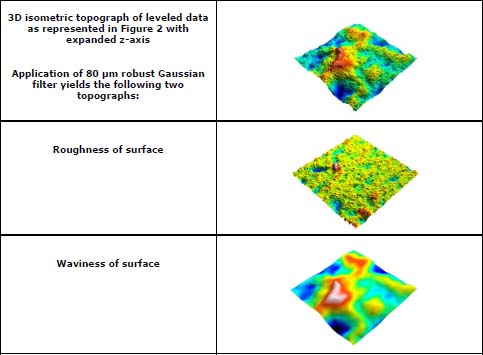

A robust Gaussian filter was applied to the 3D surface leveled data graphically shown in columns 2 and 3 in Figure 1. In one operation the roughness and waviness features are extracted and surface roughness and waviness height parameter metrics calculated for each of the four photographic papers. Figure 2 provides an example of the 3D surface data of unhardened Ilford Glossy photographic paper filtered with a robust Gaussian filter of 80 µm; surface roughness and waviness height parameters are listed in Table 3. The roughness and waviness height parameters provide a quantitative measure of the observations made from the false color contour and 3D isometric plots. The small standard deviation of the average roughness Sq value, Table 3, shows the homogeneous nature of the paper surfaces, which in turn demonstrates the high manufacturing standards of the companies making photographic papers and the demand for consistency and quality required by photographers.

As would be expected, the waviness height parameters Sq of Ilford Glossy papers is of greater magnitude than the roughness features shown in Table 3; the waviness Sq of Ilford Glossy is about 5 times greater than its roughness Sq.

The above analysis of height parameters appears to be well suited for the quantifiable characterization of glossy photographic papers and could well be applied to any photographic paper combinations of surface texture and sheen type.

Table 3: Roughness and waviness height parameters of Ilford Glossy developed without hardener (Group A)

Figure 3 shows the Ilford Glossy paper developed with hardener in the fixer bath. As before, the first column shows a black and white fully focused bright field specular image; the second shows a contour plot of the 3D data in false color; the third displays a false color 3D isometric plot; and the fourth shows the black and white bright field image overlaid onto a 3D isometric plot. The overall vertical range (z-depth) for the false color contour plots and for both sets of 3D isometric views is from 0 to 7 µm.

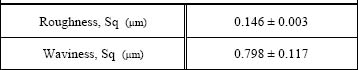

When comparing the optical/reflection properties of the gelatin surface of the developed-withhardener, group B, images in Figure 3 to those developed-without-hardener, group A, images in Figure 1 there is a difference in the reflection properties. Both group A and B views of the Ilford paper shows similar smooth glossy surfaces peppered with small pits or pores. In comparing the false color contour and 3D isometric plots of both groups, those of group B show a distinct decrease in vertical range. The reduction in vertical range of group B is confirmed by the decrease in height parameters, Table 4. A quick glance at Tables 3 and 4 to compare the roughness Sq, and waviness Sq of both papers shows a considerable difference: the decrease of roughness Sq is from 0.218 µm (group A) to 0.146 µm (group B), a 33% drop; and waviness Sq decreases 21% from 1.016 µm to 0.798 µm. The addition of aluminium sulfate hardener to the developer will affect the gelatin by minimizing swelling and increasing its melting point. The hardener acts as a tanning agent increasing the bonds or cross-linking between collagen molecules composing the gelatin matrix (Kodak MSDS 1990; Neblette 1962). The hardening has a direct and notable effect on the surface topography and sheen of Ilford Glossy.

The decrease in roughness in the hardened Ilford Glossy paper shows up as an increase in surface sheen (Elias et. al. 2006). As can be observed, the eye is sensitive to minute changes in appearance of surface texture and gloss yet to quantify these changes it is necessary to measure the topographical changes taking place in the sub-micron and nanometer ranges.

Table 4: Roughness and waviness height parameters of Ilford Glossy developed with hardener (Group B)

Confocal microscopy has allowed for the improved qualitative and quantitative characterization of the surface topography of the unhardened (group A) photographic papers, and for following the decrease of fine surface changes in roughness and waviness effected by hardening (group B) the gelatin with aluminium sulfate.

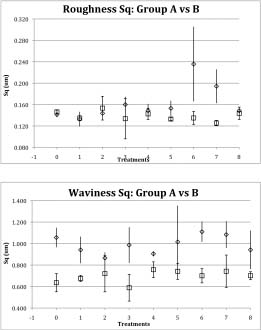

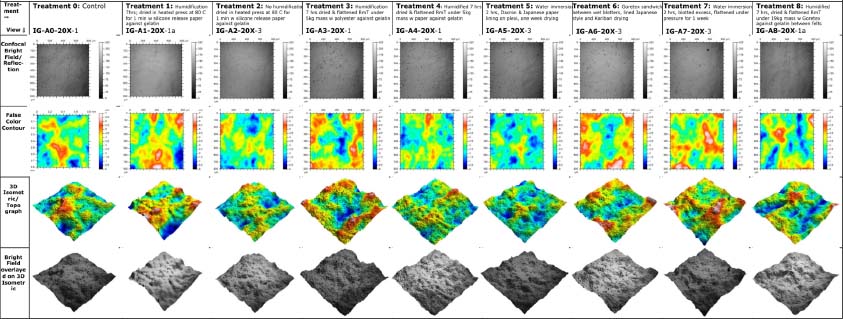

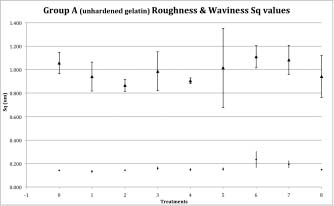

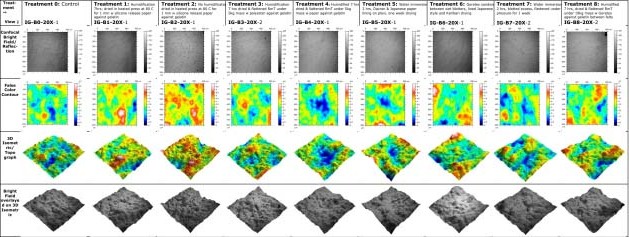

The surfaces changes of the unhardened Ilford Glossy double weight silver gelatin photograph papers subjected to eight different humidification, wetting, flattening and drying treatment protocols described in Table 2 were monitored with µsurf confocal scanning disc microscope. Figure 4, Figure 5, and Table 5 summarize all the data for the treated unhardened Ilford glossy photographic paper. Figure 4 displays the graphic results of the photographic papers that have undergone the different treatment regimens. Each row presents different views of an area measuring 800 x 800 µm2:

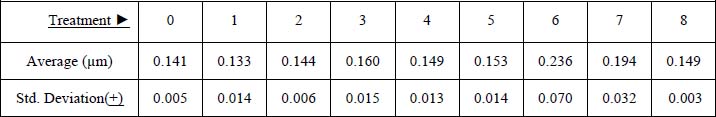

Table 5: Roughness Sq of Ilford Glossy photographic papers before and after conservation treatments. Filter, robust Gaussian 80 μm; all measurements in μm.

Surface similarities and differences are exemplified in the third and fourth row 3D graphical representations. The overall vertical z-depth range for the false color contour plots and for both sets of 3D isometric views is 0 to 7 µm, and was established by treatments 6 and 7. These two treatments appear to have had the greatest effect on the surface thereby setting the z-depth.

The first column in Figure 4, ‘Treatment 0 (Control)’, shows the four views of the control sample per row as in Figure 1. Column ‘0’ in Table 5, lists the roughness root-mean square deviation height parameter, Sq, of the control paper’s three areas sampled along with the Sq average and standard deviation. The low roughness Sq standard deviation describes a homogeneous surface of the Ilford glossy paper: average Sq of 0.141 µm with standard deviation of 0.005 µm.

‘Treatment 1’ protocol, Figure 4, (humidified for 7 hours at room temperature; dried and flattened in a dry-mount press at 80 C for one minute with silicone release paper in contact with the gelatin) demonstrates the drastic effect of heat on unhardened humidified gelatin. The most striking difference is the obliteration of the dark spots in the reflection view and the pits in the isometric view, and the overall ‘smoother’ look and increased gloss. This is corroborated by the surface topography data. The surface roughness is reduced by approximately 6% compared to control’s as observed in the surface height parameters, Sq, shown in Figure 5 and listed in Table 5: average Sq of 0.133 µm with standard deviation of 0.014 µm. The surface waviness has also decreased, Figure 5. In this case the flattening of the humidified Ilford glossy photographic paper with heat and pressure has allowed the gelatin surface to be totally reformed as observed by the almost complete eradication of dark spots and pits, and decrease in surface roughness with its corresponding increase in sheen, and decrease in waviness (Elias et al. 2006). The silicone release paper in contact with the gelatin surface appears to have had an insignificant role in affecting surface roughness and sheen.

‘Treatment 2’ protocol, Figure 4, (no humidification; flattened in a dry-mount press at 80 C for one minute with silicone release paper in contact with the gelatin) has not altered the gelatin surface much. The roughness Sq average and standard deviation are similar to the control values. Interestingly, the dry-mount flattening considerably decreased the waviness Sq by about 18%, Figure 5. The surface roughness of the dry gelatin appears to be impervious to temperature alone but surface waviness is not. Since waviness is related to the other layered components of baryta and paper, it is likely that the temperature dried and the pressure flattened the paper component thereby decreasing the overall waviness. This heat treatment approach may merit consideration only for the reduction of waviness in photographic papers.

‘Treatment 3’ protocol, Figure 4, (humidified 7 hours at room temperature; dried and flattened at room temperature under weights with a polyester non-woven in contact with the silver gelatin emulsion) has not had much of a flattening effect. The images show surface roughness to have increased and the average roughness Sq height parameter is14% greater, Figure 5 and Table 5. Waviness does not appear to have changed much compared to the control. This is also witnessed in the average waviness Sq height parameter that is slightly less than the control with a large standard deviation, Figure 5.

‘Treatment 4’ protocol, Figure 4, (humidified 7 hours at room temperature; dried and flattened at room temperature under weights with a highly calendered paper in contact with the silver gelatin emulsion) has had a similar effect on the gelatin surface as that in treatment 3. The surface roughness has increased slightly, approximately 6%, Figure 5 and Table 5, and the waviness has decreased significantly and more so than in treatment 3, Figure 5. Note that treatments 3 and 4 were exactly the same and differed only in the type of material placed against the gelatin surface: treatment 3 used a polyester nonwoven and 4 used a highly calendered paper. The calendered paper used against the gelatin surface was useful in that it imperceptibly increased the roughness (treatment 4 average roughness Sq = 0.149 ± 0.013 µm versus treatment 0/control average roughness Sq = 0.141 ± 0.005 µm) thereby not altering sheen much, and significantly decreased the waviness; it is the second lowest average waviness Sq of all treatments, Figure 5.

Treatments 5 through 9 were more interactive and aggressive involving immersion of the photographic paper in water, lining and drying and flattening under considerable pressures. Some of these treatments have considerably affected both surface roughness and waviness. ‘Treatment 5’ protocol, Figure 4, (water immersion for 20 minutes; lined with Dacron cloth and Japanese paper on a rigid Plexiglas support; allowed to air dry for one week before removal from Plexiglas) does not appear to have changed the surface roughness or waviness much. Comparing the control with treatment 5 shows the average roughness Sq (0.153 ± 0.014 µm) is about 9% higher than the Sq average for treatment 0/control (0.141 ± 0.005 µm). The average waviness Sq is lower than the treatment 0/control value but, interestingly, its standard deviation is the largest of any of the other waviness average Sqs, Figure 5. Such a large standard deviation indicates that the surface waviness has been greatly affected and is no longer homogeneous. The Dacron cloth weave pattern appears to be in the same range as the waviness wavelength of the Ilford Glossy paper. Hence, it is possible that the Dacron cloth weave pattern may have transferred through the Japanese paper lining to the photographic paper and thus greatly affected the waviness of the gelatin surface. In light of the large standard deviation in waviness Sq, these results call into question the usefulness and appropriateness of Dacron lining treatments for flattening glossy photographic papers. It may also be possible to extend this observation to other glossy and fine textured and high sheen photographic papers.

Another extremely interactive approach is ‘Treatment 6’, Figure 4, (humidified between wet blotters and Gore-Tex sandwich; lined Japanese style and dried emulsion side ‘in’ on a Karibari drying board). In this case the photographic glossy paper is lined only with Japanese paper. The views in Figure 4 show roughness to have increased considerably compared to the other treated gelatin surfaces, and waviness appears to have remained almost the same. The surface metrics for this treatment are in agreement with the visual assessment. The surface average roughness Sq and standard deviation (0.236 ± 0.070 µm) are the highest of all treatments. The roughness Sq is 67% greater than the treatment 0/control Sq value, Figure 5 and Table 5, in contrast to the average waviness Sq, which is slightly more than treatment 0/control, Figure 5. The behavior of these height parameters is opposite to the previously discussed treatment 5.

In both treatments 5 and 6 the photographic papers were lined; treatment 5 with Japanese paper and Dacron cloth, and treatment 6 with Japanese paper only. Comparing the average waviness Sq values, Figure 5, shows the Dacron lining value to be lower than that of the Japanese paper only lining. The standard deviation of waviness of the Dacron lining is much greater than that of the Japanese paper lining. This lends credibility to the above-mentioned statement that the Dacron cloth weave is the likely contributor to the major increase in standard deviation of waviness and greater heterogeneity of the gelatin surface of the Ilford Glossy paper in treatment 5.

Comparison of the average roughness Sq values of treatments 5 and 6 show the reverse pattern; Sq of treatment 5 is 0.153 ± 0.014 µm and that of treatment 6 Sq is 0.236 ± 0.070 µm. The high average roughness Sq for treatment 6 is puzzling since both apply similar lining methods and are air-dried. The cause for the marked increase in surface roughness of the gelatin surface is likely to be the nature of tension drying. In treatment 5 the lower roughness values could be due to the procedural step of lining the Dacron and Japanese paper onto Plexiglas, which restricts expansion and contraction. In contrast to treatment 6 where the Japanese paper lined photograph paper is tension air-dried allowing for greatest amount of expansion and contraction thereby having an adverse effect on the gelatin surface roughness.

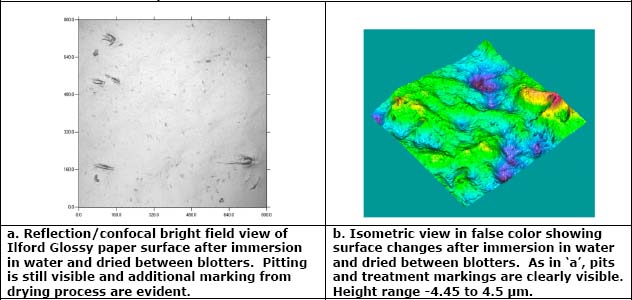

‘Treatment 7’ protocol, Figure 4, (water immersion for 2 hours to fully swell gelatin; dried with blotters to remove excess moisture at 10, 20, 30 and 60 minutes; then dried and flattened under pressure for 1 week with a polyester non-woven in contact with the silver gelatin emulsion) has affected roughness more than waviness. The average roughness Sq increased by 38% (Sq =0.194 ± 0.032 µm) over treatment 0/control and is the second highest increase after treatment 6, Figure 5 and Table 5. There is a 27% difference between the average roughness Sqs of treatments 7 and 5, where two-hour water immersion was also used. In this treatment the fully wetted paper was placed against a thin polyester non-woven Hollytex, then the verso of the photograph was blotted at several intervals during the first hour to remove excess moisture. The blotting action and having a polyester non-woven against the silver gelatin matrix may well be the causes for the disruption of the surface. Two types of disruption have occurred: the increase of roughness as described above and the visible additional markings, four on the left and one in the lower right shown in Figure 6. The markings are depressions, different from the original spots and pits, with stretch-like marks along their sides indicating there was a small yet distinct lateral movement toward the lower right corner when the weights were placed on top of the drying system. The markings are likely from protruding fibers on the polyester non-woven having been pressed against the swollen silver gelatin matrix during the drying process. In this treatment, waviness was not affected as much as roughness. Figure 5 shows the average waviness Sq value for treatment 7 to be slightly larger than treatment 0/control.

‘Treatment 8’ protocol, Figure 4, (humidified 7 hours at room temperature; dried and flattened using 42 lbs/19 kg of weights at room temperature with Gore-Tex, smooth side, in contact with the silver gelatin emulsion and wool felts) shows little change when compared to treatment 0/control: the average roughness Sq is slightly higher (Sq = 0.149 ± 0.003 µm), Figure 5 and Table 5; and average waviness Sq is lower, Figure 5. The materials used in the flattening process in this case have had a positive effect. Goretex, a smooth low textured flexible film, placed against the humidified gelatin under pressure did not appear to affect the gelatin surface much and yielded a surface roughness similar to that of the original, and decreased waviness. Of all the treatment protocols, this may be one of best methods for flattening photographic papers for Goretex does not interact much with the gelatin surface as observed in both surface roughness which is maintained close to controls, and the decrease in waviness.

All eight protocols studied have had small to large impacts on the gelatin surface. The humidification treatments 2, 3, 4 and 8, and, treatment 5 (20 minute immersion in water) appear to have had small and imperceptive effects on the gelatin surface texture: original high gloss has been maintained and changes to average surface roughness Sq values have been minimal. Interestingly and as mentioned earlier, treatment 1 (humidification for 7 hours and dry-mount press flattening at 80°C) resulted in significant decreases in both roughness and waviness height parameters and removal the dark spots and pits thereby providing a smoother and glossier look, Figure 4. These results are unique; it has had a reverse or contrary effect in roughness compared to all other treatments, and a considerable but not the greatest lowering of waviness.

Of all treatment protocols the Ilford Glossy photographic papers were subjected to, treatments 6 and 7 resulted in the greatest alterations of surface roughness and waviness on the glossy gelatin. In this set of treatments of unhardened glossy photographic papers, the delivery of moisture by humidification or immersion to swell gelatin and relax paper fibers appears be of less importance than the flattening process. Whereas all materials used in flattening are important, the most critical aspect appears to be the nature and quality of the material in contact with the gelatin surface. It seems that the materials coming in contact with the gelatin must be ‘un-reactive’ in that they do not affect or alter the gelatin surface in any way.

Results and Discussion: Ilford Glossy hardened, Group B, Photographic Papers Subjected To Humidification, Wetting, Flattening And Drying Conservation Treatment Regimens

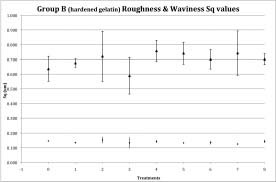

The surfaces changes of the hardened Ilford glossy double weight photograph papers subjected to eight different humidification, wetting, flattening and drying treatment protocols described in Table 2 were monitored with the µsurf confocal scanning disc microscope.

Figure 7 and Figure 8 summarize all the data for the treated hardened Ilford Glossy photographic paper. Figure 7 displays several different views of the results of the photographic papers that have undergone the different treatment regimens. The four different views of the results of the eight treatment protocols performed on the hardened glossy paper displayed in Figure 7 do not appear much different to those of the unhardened papers, Figure 4.

Figure 9 compares the metric data of average roughness Sq and waviness Sq values for the unhardened and hardened glossy papers. Interestingly, Figure 9 shows that the average roughness Sq values for the unhardened and hardened glossy papers are practically the same for treatments 1, 2, 4 and 8. The average roughness Sq values for treatments 3 and 5 are similar and within one standard deviation. It is surprising that the hardener has not affected the surface roughness and sheen. The minimal to low differences of average roughness Sq values between the unhardened and hardened papers is a strong indication that the surface roughness’s of both unhardened and hardened papers, interestingly enough, behave the same under these varied treatment regimens.

The most dissimilar average roughness Sq values are for treatments 6 and 7. These two treatment protocols for the unhardened glossy photographic papers caused the greatest alterations in roughness and waviness of the glossy gelatin surface texture. The lining and drying methods of these two procedures has not had the same effect with the hardened papers. Therefore, it is likely that the hardened gelatin surface is hardier and less susceptible to roughness alteration by the lining techniques of these two procedures than that of the unhardened papers. And this also implies that if the surface has been made hardier and less changeable through hardening, it has done so without affecting the surface roughness as seen in all the other treatment results.

The surface waviness of the hardened papers has been affected more than its roughness. The difference in surface waviness between the unhardened and hardened papers is considerable and the waviness of hardened papers is consistently lower throughout all treatment protocols, Figure 9. The percent decrease in average surface waviness Sq values of the unhardened to hardened papers ranges from 15% to 40%. The percentage drop is greatest for Treatment 0/Control at about 38%, and Treatment 6 at 36%, and least for Treatments 2 and 4, at 22% and 16%.

The surface metrological technique of confocal scanning disc microscopy is a non-perturbing (non-contact, non-invasive and non-destructive) instrumental method that has shown its potential to in situ document and characterize the fine surface structure of a glossy silver gelatin photographic paper, and monitor surface alterations effected by various humidification and flattening treatment protocols. The nature of the 3D data -contour, 3D isometric and 3D B&W overlay plots - is such that they fully complement the specular bright field images providing more information, improving and confirming visual analysis of physical and topographical features, which can be quantified, measured, expanded and highlighted, and differentiated from optical phenomena.

The surface changes of the Ilford Glossy silver gelatin photograph papers monitored clearly demonstrate the application of confocal scanning disc microscopy to follow fine changes effected through conservation treatments. Interestingly, all treatments have affected the Ilford Glossy gelatin surface and irreversibly altered it. The macro changes can be observed visually and the finer alterations, which are imperceptible to the eye, require surface metrology instrumentation for quantification. Conservators will always rely on visual methods to qualitatively evaluate condition and the effects of treatment, yet research information derived from 3D quantitative surface studies can significantly advance the field and further train the already keen eye and manual skills of the conservator and restorer. Confocal scanning disc microscopy has many potential applications for the conservation and restoration of photographs in which fine surface features and smooth glossy surfaces are defining characteristics. It and other surface metrology techniques especially shows promise for quantitative evaluation of treatment regimens, and for condition monitoring of photographs in storage or on loan over term periods.

The high level of surface detail that surface metrology measurements provide the conservator will permit for the monitoring and evaluation of surface changes at a level beyond human visual detection, and at the observable level. Perhaps this powerful technique could assist conservators to learn to effect necessary conservation changes to historic and artistic photographic works below human visual detection levels. It also demonstrates the great potential of surface metrology to other areas of cultural heritage preservation and conservation.

P. Ravines acknowledges the support of Hans Hermann Schreier, President and CEO NanoFocus AG, and the Andrew W. Mellon Foundation; Lou Bergner for assistance with Excel tables and graphs; and Ralph Wiegandt, Senior Project Conservator, George Eastman House International Museum of Photography & Film.

Arney, J.S., Pollmeier, Klaus; Michel, J. 2002. ‘Technique for Analysis of Surface Topography of Photographic Prints by Spatial Analysis of First Surface Reflectance.’ J. Imag. Sci. & Technol., 46(4): 350.

Chen, Jiuan-juan. 2003. ‘The Evaluation of the Surface Change of Silver Gelatin Prints: The application of edge reflection analysis and other methods to evaluate the effect of eight drying/flattening Procedures.’ Internal report. Advanced residency program, George Eastman House, Rochester, New York, 61.

graphicsatlas-dot-org accessed 12/2008

Dune, C., Grinde, L. and Wiegandt, R. 2005. ‘Characterization of black-and-white silver gelatin fiber-based photographic prints.’ Topics in Photographic Preservation 11.

Elias, M., de la Rie, R., Delaney, J.K., Charron, E., and Morales, K.M. 2006. ‘Modification of the surface state of rough substrates by two different varnishes and influence on the reflected light.’ Optics Communications, 266, 2, 586-591. doi:10.1016/j.optcom.2006.05.051

Funderburk, Kit. 2007. ‘A Guide to the Surface Characteristics: Kodak Fiber Based Black and White Papers.’ Rochester: Eastman Kodak, 6

Grynszpan, R.I., Pastol, J.L., Lesko, S., Paris, E., and Raepsaet, C. 2004. ‘Surface topology investigation for ancient coinage assessment using optical interferometry’, Applied Physics A 79: 273-276.

ISO/DIS 25178-2. 2008. ‘Geometrical product specifications (GPS) – Surface texture: Areal – Part 2: Terms, definitions and surface texture parameters.’ Geneva: International Organization for Standardization.

Kodak. 1977. ‘Kodak Professional Darkroom Dataguide.’

Kodak. 1990. ‘Material Safety Data Sheet.’

Messier, P. and Vitale, T. 1994. ‘Effects of Aqueous Treatment on Albumen Photographs.’ Journal of the American Institute for Conservation, 33: 257-78

Minsky, M. 1988. ‘Memoir on inventing the confocal scanning microscope’. Scanning 10: 128-138.

Neblette, C.B. 1962. ‘Photography: its materials and processes.’ New York: Van Nostrand, 251.

Passafiume, Tania. 2001. ‘A silver gelatin DOP sample book and a characteristic catalogue of the Edward Weston collection at the George Eastman House.’ Internal report. Advanced residency program, George Eastman House, Rochester, New York.

Ravines, P., Wiegandt, R., and Wichern, CM. 2008. ‘Surface characterization of daguerreotypes with the optical metrological technique of confocal microscopy.’ Surface Engineering, 24 (2) 138-146.

Ravines, P., Wiegandt, R., Hailstone, R. and Romer, G. 2008. ‘Optical and surface metrology applied to daguerreotypes’. In Conservation Science 2007: Papers from the Conference held in Milan, Italy 24–26 May 2007, London: Archetype Publications, 131-139.

Sotiropoulou, S. and Wei, W. 2006. Non-contact method for the documentation, evaluation and monitoring of conservation treatments for icons, ICOM-CC International Conference, ‘Icons: Approaches to Research, Conservation and Ethical Issues’, New Benaki Museum, Athens, Greece, 3-7 December 2006.

Stout, K.J. 2004. ‚Development of Methods fort he Characterisation of Roughness in Three Dimensions.’ London: Penton Press, 98, 130.

Wie, W., Stangier, S., and de Tagle, A. 2005. “In situ characterization of the surface of paintings before and after cleaning using white light confocal profilometry” in Proceedings of Art ‘05 – 8th International Conference on Non-Destructive Investigations and Microanalysis for the Diagnostics and Conservation of the Cultural and Environmental Heritage, Lecce, Italy, 15-19 May 2005. (On CD).

Whitehouse, D. 2002. ‘Surfaces and their measurement.’ New York: Taylor & Francis, 1.

PATRICK RAVINES

Art Conservation Department, Buffalo State College

JIUAN-JIUAN CHEN

Paul Messier, LLC.

CHRISTIAN M. WICHERN

Nanofocus, Inc.

Papers presented in Topics in Photographic Preservation, Volume Fourteen have not undergone a formal process of peer review.

Figure 1. Visual displays of data for one of the control samples of Ilford Glossy silver gelatin photographic paper developed without hardener, group A (Sample displayed is IG-A0-20x-1; 20x objective; measurement field 800 x 800 μm2; z-range 0 – 7 μm)

Figure 2 – Surface data array of unhardened Ilford glossy photographic paper i.e. control (IG-A0-20x-1) subjected to a robust Gaussian filter (80 μm) to extract roughness and waviness information

Figure 3. Visual displays of data for one of the control samples of Ilford Glossy silver gelatin photographic paper developed with hardener, group B (Sample displayed is IG-B0-20X-1; 20x objective; measurement field 800 x 800 μm2; zrange 0 – 7 μm)

Figure 4. Comparison of Glossy unhardened (group A) papers before and after treament

Figure 5. Comparison of control to treated unhardened (Group A) Ilford Glossy photographic paper’s roughness Sq and waviness Sq, root mean square height deviation: circle marker = roughness Sq and triangle marker = waviness Sq.

Figures 6. Reflection and isometric views of Ilford Glossy papers subjected to different treatment protocols.

Figures 7. Comparison of Glossy unhardened (group B) papers before and after treament

Figure 8. Comparison of control to treated hardened (Group B) Ilford Glossy photographic paper’s roughness Sq and waviness Sq, root mean square height deviation: circle marker = roughness Sq and triangle marker = waviness Sq.

Figure 9. Comparison of roughness Sq and waviness Sq, root mean square height deviation, of Ilford Glossy unhardened (Group A) and hardened (Group B) control and treated photographic papers: diamond marker = Group A and square marker = Group B.